Closing the loop – digital manufacturing solutions for your production

How to take digitalization to the next level with the right solutions and data

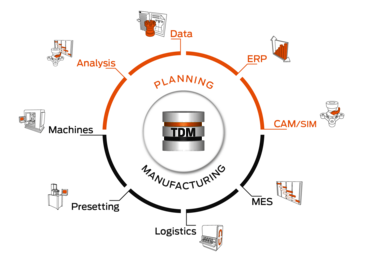

Every machining company has an individual production set-up: Products, processes, tools and machines. But they all have one thing in common: They want the highest possible efficiency, safe processes, availability of resources and a consistently high level of quality of the products. And this is precisely where digital manufacturing solutions from TDM Systems come into play: We provide digital solutions for tool and machine data for every company profile. Start the digital transformation in your production now and benefit from absolute transparency on the shopfloor.

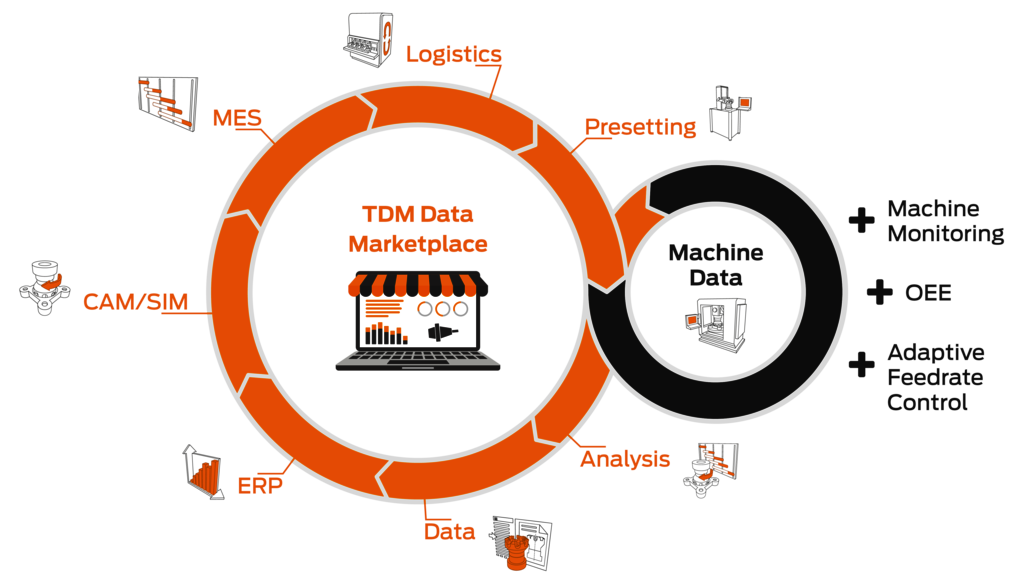

With its five software lines, TDM Systems offers comprehensive options for managing tool and machine data. TDM ClassiX is our most comprehensive product line with a large number of modules and the option to adapt them to your requirements via customizing. TDM Global Line is based on state-of-the-art software development with great features in data management, powerful performance in its global application as well as options for individual configuration. TDM Cloud Essentials is our smart cloud solution for easy entry into tool management, ideal for smaller machining companies. The TDM iCut and TDM appCom solutions are new additions to the TDM Systems portfolio. They involve adaptive feed control as well as machine monitoring and OEE analyses. These solutions provide a full overview of the machine.

Your digital manufacturing solution: From the basics to specific functions

The digital manufacturing solutions from TDM Systems are characterized by the fact that they can be flexibly combined and are scalable. The TDM solutions are modular and can be individually combined. No matter which strategy you use to start digitalization in your shopfloor. Whether with digital tool data and 3D twins in the CAM planning area or with digital crib management – the basis is the TDM database and, building on this, the modules and interfaces tailored to your requirements. The scalability also plays an important role: Achieve your digital strategy and start with a small application (TDM can be started from a single-location solution) and expand the application up to an international corporate solution. With our wealth of experience from 30 years of software and customer projects, we know what is important. In addition to on-premise solutions, we also offer cloud applications and mobile, browser-based solutions.

The central database – the single point of truth

The most important part of your TDM software will be the central database and the data it contains. This is because the database determines the success of your digitalization strategy in production. The software is structured in such a way that both simple and more complex tools can be mapped as digital twins. High-quality, consistent tool data generates added value and supports the manufacturing processes. TDM Systems therefore offers users comprehensive support for data generation and maintenance. In addition to the software solutions for digital data generation and modification, the TDM experts also offer data consulting services. New TDM users can be advised on the most effective approach to data creation, especially with regard to data sources and import tools. But we are also happy to advise experienced TDM users on how to optimize their database. We also offer our customers data services and take care of setting up the database and data creation.

Integrated tool and machine data

TDM not only offers digital manufacturing solutions for the management of tool data, but machine data can also be recorded, analyzed and evaluated. With the TDM iCut and TDM appCom software lines, you achieve transparency around the machine, reasons for malfunctions become transparent and optimization potential becomes visible. The adaptive feed control TDM iCut measures the cutting process up to 500 times a minute and digitally optimizes the feed rate – continuously. TDM appCom, the digital solutions for production optimization and OEE analysis, tracks all activities around the machine, analyzes them continuously and visualizes the performance in a clear dashboard. Both software lines are easy to install and offer immediate benefits to production. Valuable data from the machine is selected and can be used for further analysis.

Start now: Simple entry into tool crib management

With the TDM tool management manufacturing solutions, you can easily get started with the tool crib and save costs. You know the challenges in the tool crib:

- Missing tools

- Uncertain stocks

- Overview of orders and receipts

- Location of tools, etc.

The TDMstoreasy cabinet software makes it easy to get started with tool management in the tool crib. Controlled tool dispensing, transparent stocks and digitally recorded tool movements allow for an optimized ordering system and means that tool searches are reduced to a minimum. In combination with TDM ScanEasy, the mobile scanner solution, tool bookings are recorded on the shopfloor and data can be retrieved at any time.