Uniform tool data and centralized tool database offers optimum management

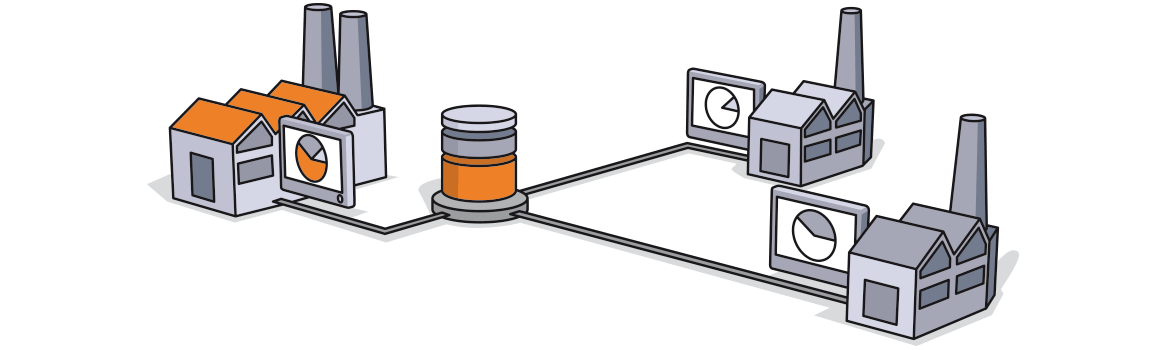

Client: From TDM's perspective, a client can be both an independent plant and a specific production area. The TDM Administrator can define clients individually and assign users to each of them. It is also possible to assign one user to multiple clients.

Client – data record allocation: Users can allocate master data to one or more clients via an allocation table. The data record can be created as multilingual. The objective is for the users of a client to only have access to the data that has been defined for them.

Client-capable TDM modules: Combine TDM Multi Plant Management with the following TDM modules:

- TDM Base Module

- TDM Tool Crib Module

- TDM Purchase Requisition Module

- TDM Fixture Management Module

- TDM Gauge and Calibration Management

- AME interfaces to CAM systems

- Interfaces to presetting devices (partially client-capable)

Client-capable data: The TDM Multi Plant Management software facilitates access to a significant portion of the production equipment data managed using TDM modules. This includes data for use of the TDM Base Module, organization of inspection equipment, or the interfaces to CAM and presetting systems.

One centralized database manages all production equipment data throughout the company. This provides an important overview of stock. The Multi Plant Management software offers an optimum database for evaluations and control functions. The transparency achieved through company-wide standards optimizes processes regarding tools and technologies.