Shopfloor organization and process optimization in manufacturing

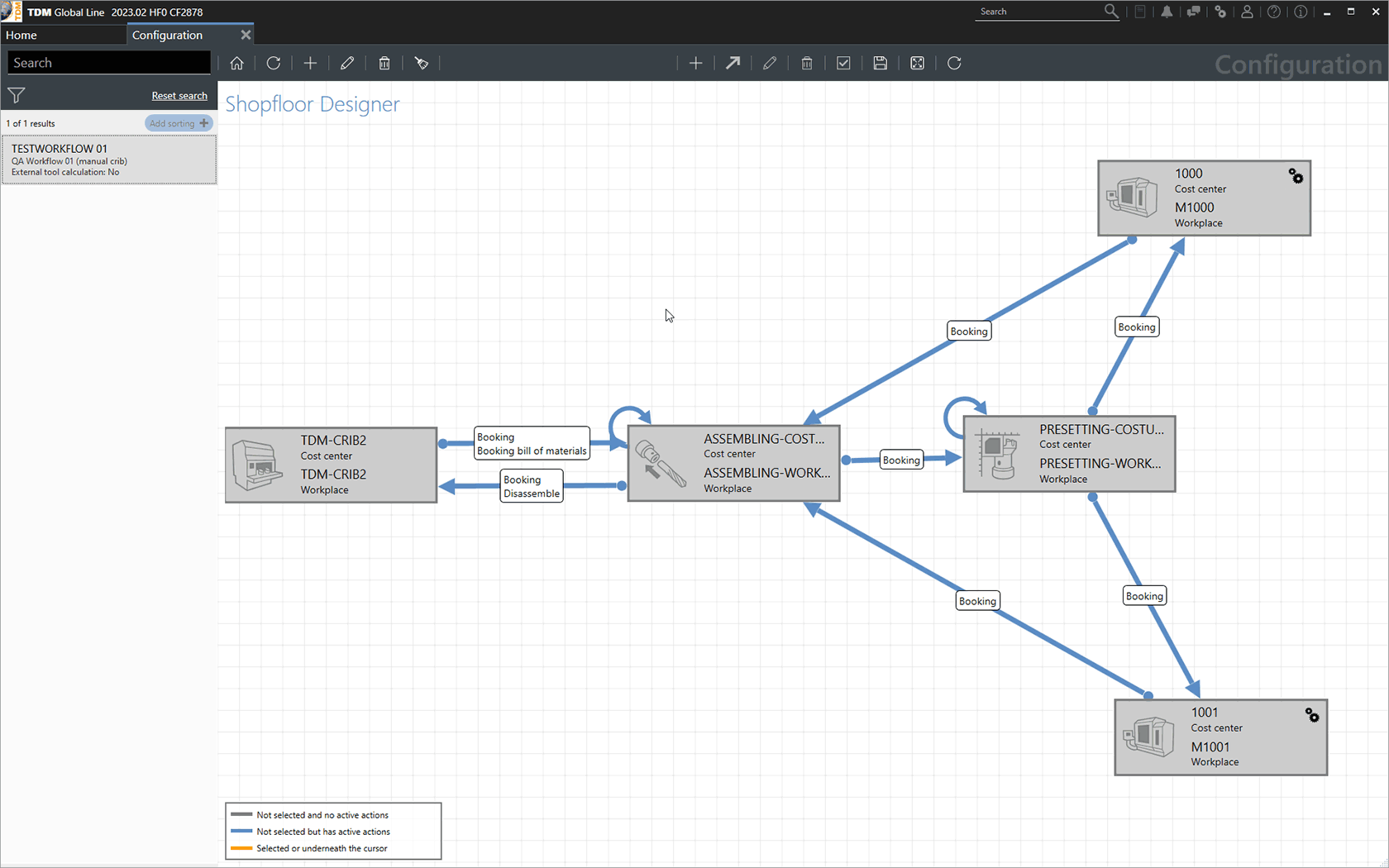

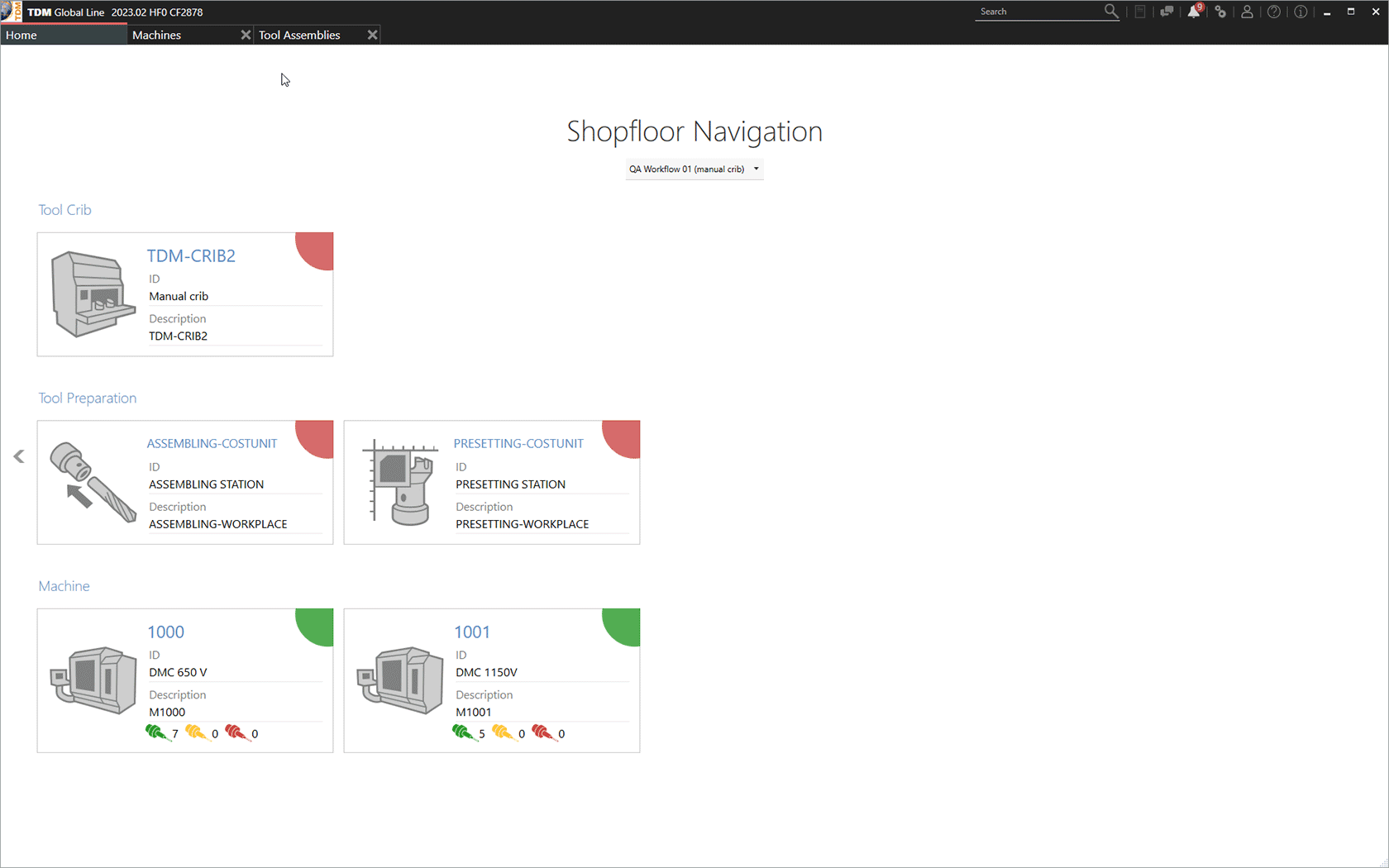

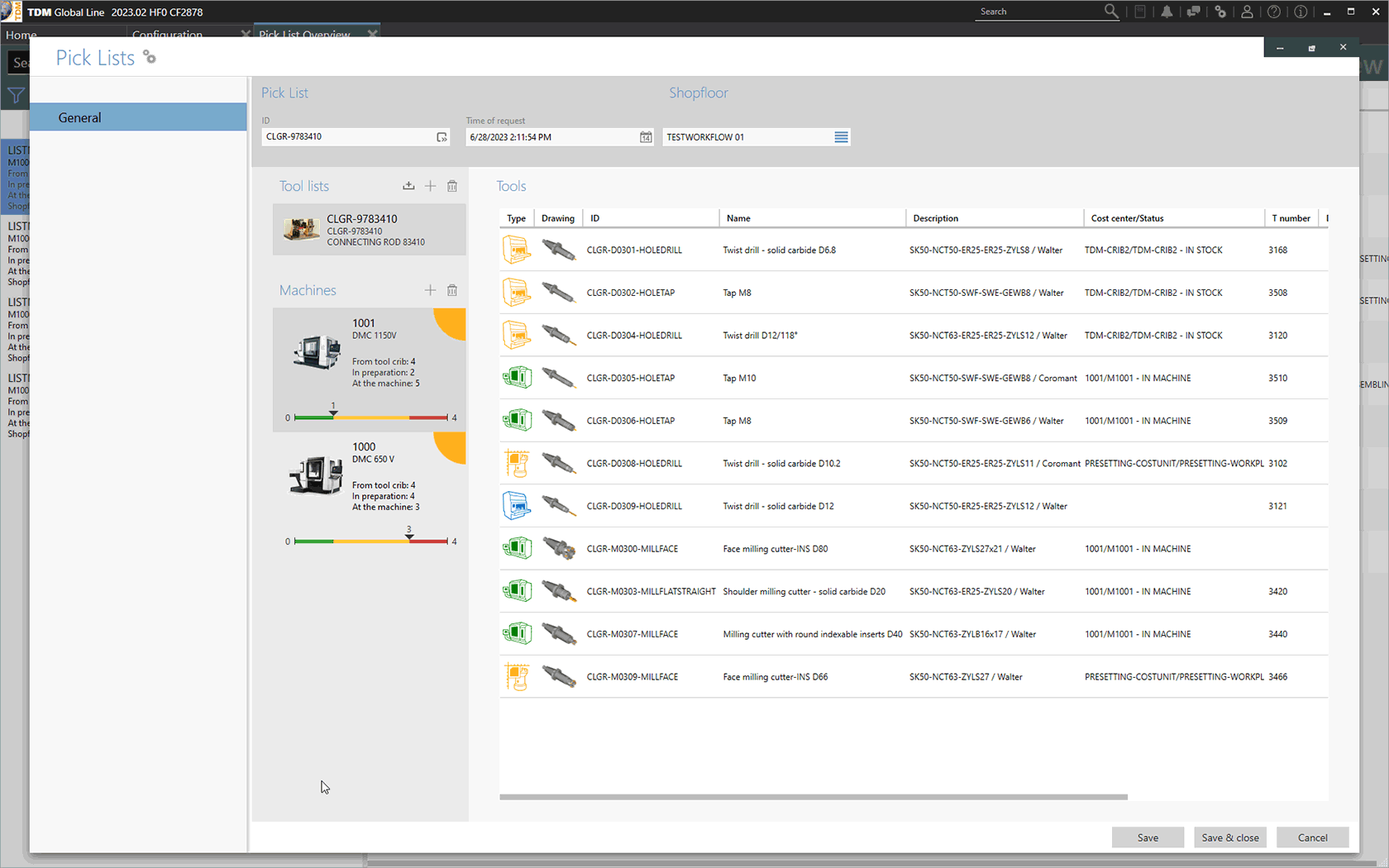

The module for shopfloor organization is used to organize digital tool management in the production environment. Visual planning of the production processes guides users through the individual tool circulation stations in a targeted manner: From the tool crib to the machine.

The software module supports various, individually configurable tool processes on the shopfloor. This delivers a high degree of transparency in the shopfloor organization of the tools and maximum utilization time of the machines.

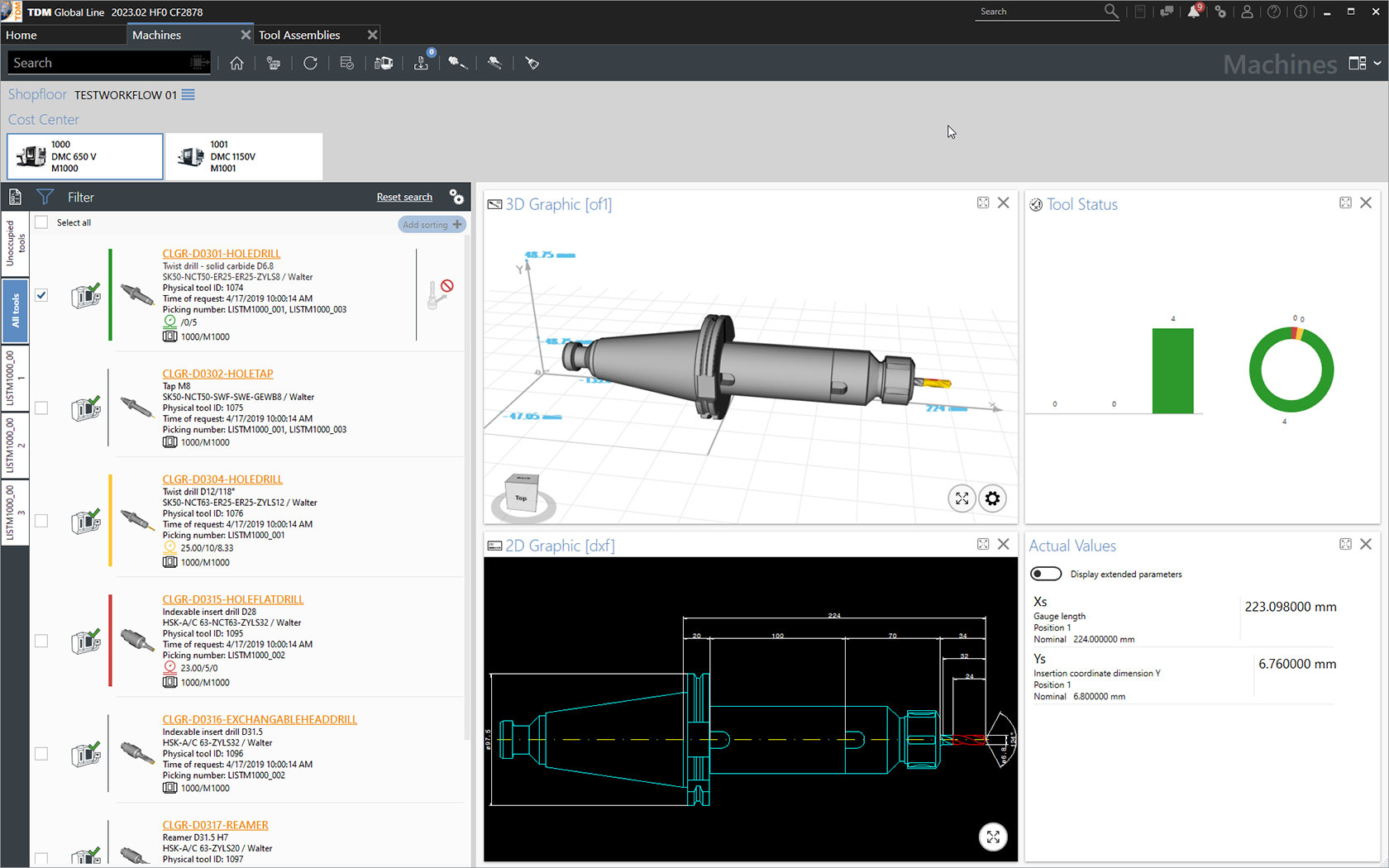

Optimizing shopfloor processes increases production

TDM Shopfloor Manager implements time-accurate and correct tool provision for the active and subsequent NC operations on the machine. Using TDM Shopfloor Manager software means that missing or incorrectly set tools are a thing of the past.

This brings the tool-related machine downtimes to a minimum. Superfluous logistics costs or unnecessary tool disassembly are then also eliminated. Tool preparation becomes more efficient, shopfloor processes more secure, and machine utilization higher.