The TDM Release 2026 features automatic and seamless data transfer the machine using a standard connection, without interruptions or intermediate manual steps. In addition, mobile apps enable quick access to data and tasks directly in the machine and tool crib environment, whereby tools can be booked directly to cost centres via barcodes and NC programmes are accessed on the go.

The main highlight of the 2026 release is the new standardized Interface “TDM Machine Data Connector”, that further supports and accelerates the automation on the shopfloor. TDM already had several dedicated solutions in place, but the new standardized machine connection from TDM can work with most current machine controls on the market. The interface already works with Heidenhain machine controls, and with Siemens and Fanuc controls as of mid-2026. This means that all tool-related information, from master-data to wear values, flows bidirectionally and without manual intervention, independent of the control system in use. This gives full transparency, allows for forward-looking planning and results in significantly higher productivity.

TDM ScanEasy, the mobile barcode scanner for the shop floor, now supports all tool crib processes and inventory, as well as quantity bookings. The significantly simplified workflows result in faster and more efficient management of items on the shop floor. In addition to querying item information, TDM ScanEasy now allows for mobile booking of tools in any situation, at the workplace or at the machine, while the new dynamic search function displays suitable item suggestions for selection after entering just a few letters.

One of TDM's biggest advantages is its high level of integrability and connectivity with other systems. As of Release 2026, TDM software can communicate with the CRIBWISE (Sandvik) manufacturing inventory management system. This includes the exchange of component data, synchronized inventories and stock postings, which can be booked in either system. By using TDM and CRIBWISE, TDM-users can implement automated ordering processes and a transparent warehouse structure for consumable tools. And thanks to the systems’ synchronization, both systems are always up to date.

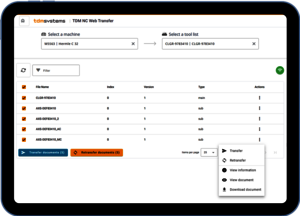

A new feature in TDM´s Integrated NC Program Manager is the TDM NC Web Transfer that enables mobile, browser-based provision of approved NC programmes. These can be available in machine-related directories for further use or transferred back after optimization on the machine. This saves time, creates greater transparency in the machine environment and increases the usability of the TDM Integrated NC Program Manager.

As calibration and testing of measuring and calibration equipment is often conducted by external suppliers, the resulting data may not be immediately available to users of the TDM Gauge and Calibration Management Module. By transferring the calibration data from external systems, users can optimize this process as well as their measurement and test equipment management.

TDM Release 2026 also offers comprehensive new features for data entry and maintenance. This ensures the efficient processing of mass data for components and complete tools, with easy conversion from inches to metric and vice versa, automatic collision data generation for large amounts of data, deletion of graphics or data in specific fields, optimised measurement of graphics and simplified assembly of complex tools.

- Press Release English (docx)

- Press Release German (docx)