TDM perfectly combines planning and production for efficient tool management

The TDM software is the link between two worlds: Virtual planning on the one side and actual production on the other. The central TDM tool database is the centerpiece of successful tool management. It makes the data available for the entire production process and helps secure a transparent data flow across all process steps. The TDM solutions for data capture and generation ensure the quality and availability of the data.

Supplier independence is a key feature of the TDM solutions, which link production systems and machines from various manufacturers. Numerous interfaces to the most common manufacturers guarantee smooth interaction and facilitate automated procedures.

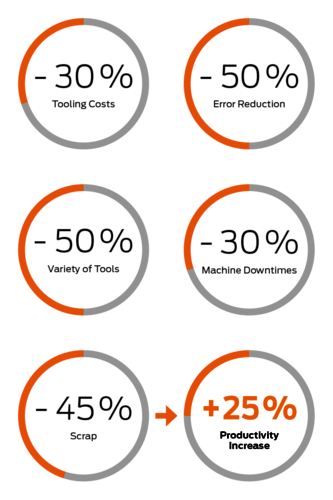

Efficient tool management increases productivity

Shorter planning times: TDM Systems is the only provider to offer application-specific tool data and graphics. These are NC-ready and available in various formats for all standard CAM systems. This guarantees reliable simulation analyses.

Time savings in tool provision: Find your tool right away, rather than spending a lot of time searching for it. Thanks to TDM, you always know where your tools are currently located, whether on the machine or in the crib.

Less machine downtime and fast lead times

When the right tool is on the right machine at the right time, you increase the productive working time by up to 30%. Even 20% higher machine utilization can already deliver 10% greater gross profit.

Reproducible cutting values: If the cutting data of your tools is stored centrally, you can use it time and time again for new orders. With TDM Global Line, you can even use it across multiple locations.

Reducing costs with the advantages of tool management

If you manage your tools consistently and transparently, you can save up to 20% tooling costs. The costs per workpiece are also reduced by up to 10% or even 20% if you process a lot of cutting data. An overview of the type, number, and crib location helps you standardize and reduce your tool variety. This in turn leads to better ordering conditions.

Efficient tool management is the prerequisite for sustainable production operations.