Improved CAM tool data thanks to integrated calculation logics

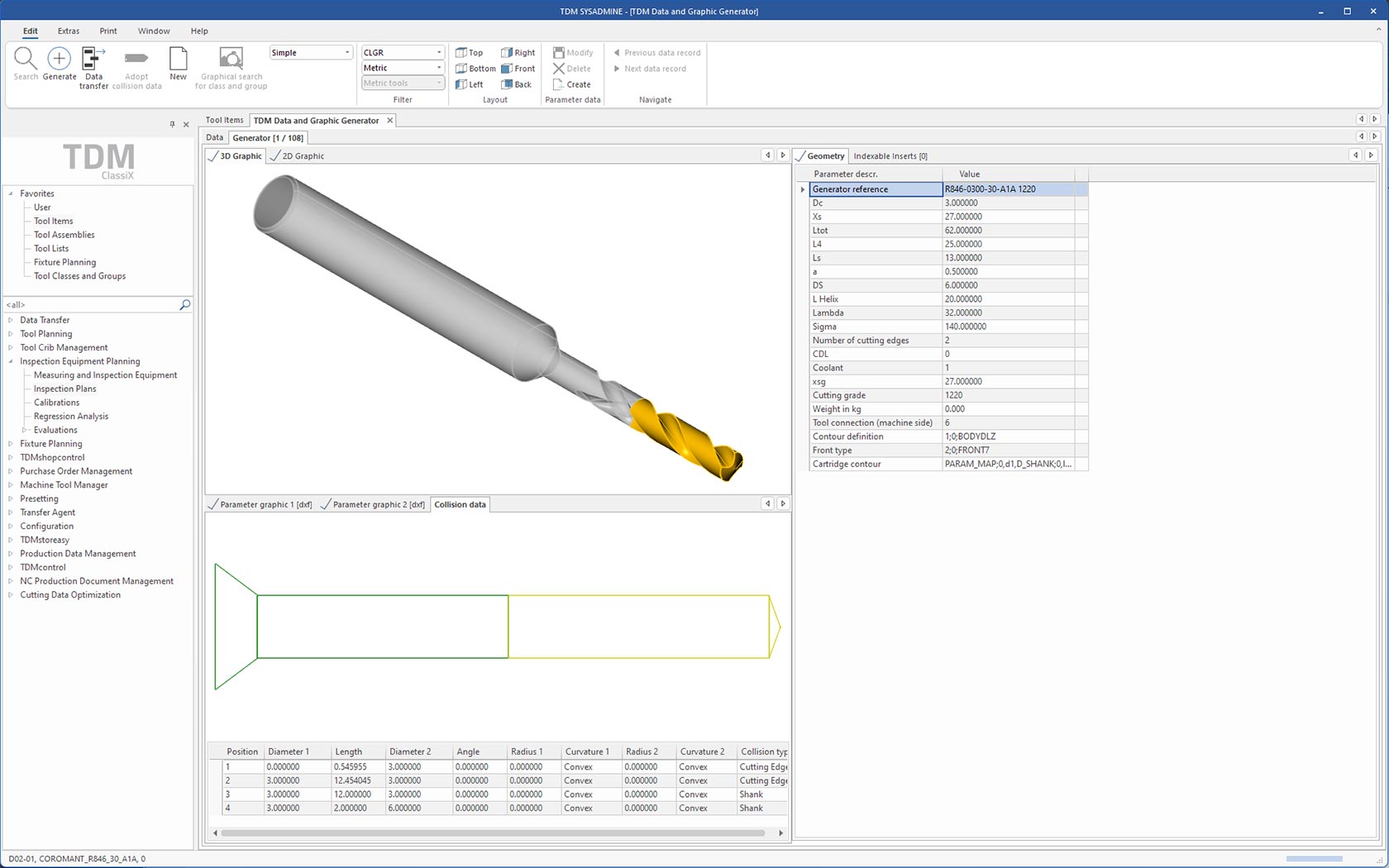

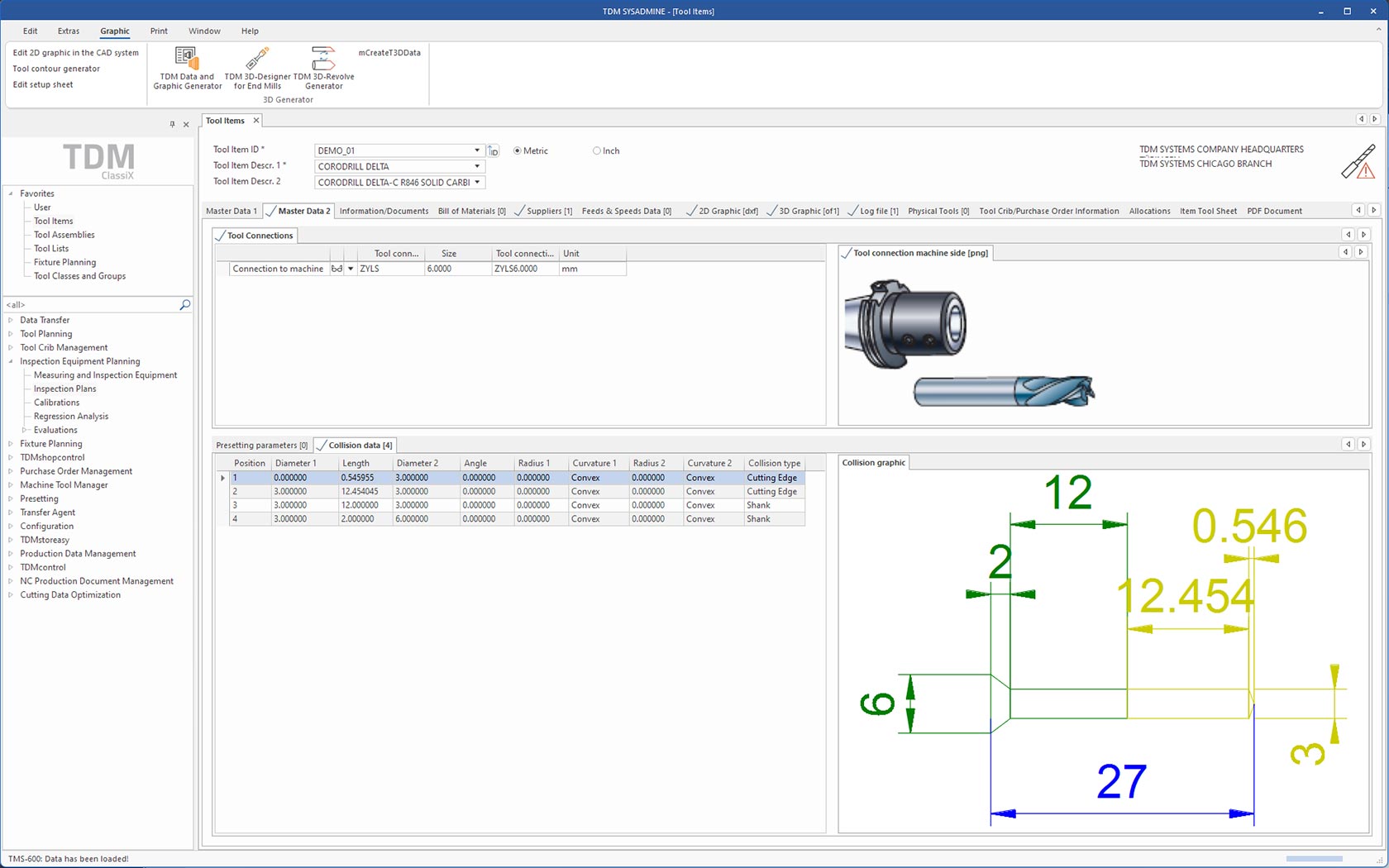

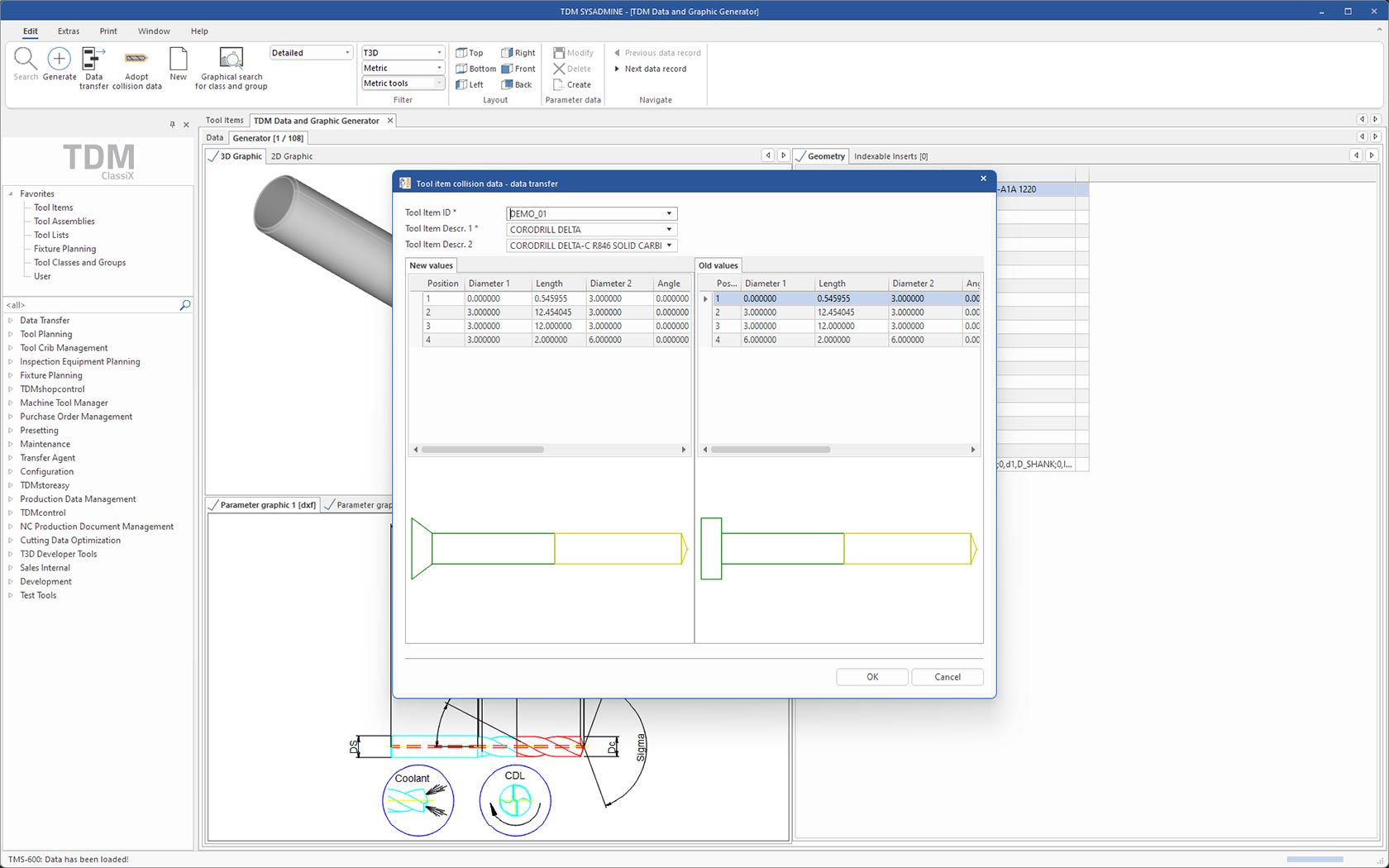

Collision data is of crucial importance for NC programming in Siemens NX and CATIA systems. But creating it takes up a great deal of time. The collision elements have to be laboriously measured in the 2D graphics. Another drawback is that no standardized data is available from other data sources. Based on user recommendations, TDM Systems is tackling this issue with the aim of automating the generation of collision data and reducing users' workload.

Improved data quality with automation and know how

The TDM Collision Data Generator uses the technical benefits of the TDM Data and Graphic Generators. The parameterized items form the basis for calculating the collision data. The logics programmed especially for this also help with accurate generation of collision data. This is why collision data generation only works in conjunction with the TDM Data and Graphic Generators: