TDM ClassiX – perfected over the years, continually developed with users and 100% field-proven

TDM ClassiX is the solution that has made TDM Systems a success. And it is the solution that, alongside the development of TDM Global Line, we continually develop and adapt so that it meets both the current and future needs of our customers. In recent years we have integrated a variety of new modules and functional improvements that are highly regarded by customers in all markets and industries. TDM ClassiX stands out thanks to its excellent range of functions as well as its exceptional integration capability thanks to the multitude of interfaces that allow it to connect to machining companies' system environments. Working closely with TDM ClassiX users and machining companies in general, we have been able to further develop TDM ClassiX so that it offers solutions to new production challenges ahead of time. TDM ClassiX users benefit from our accumulated expertise in tool data, technology and process optimization.

Innovative solutions: Identifying future challenges, and developing the solutions to meet them

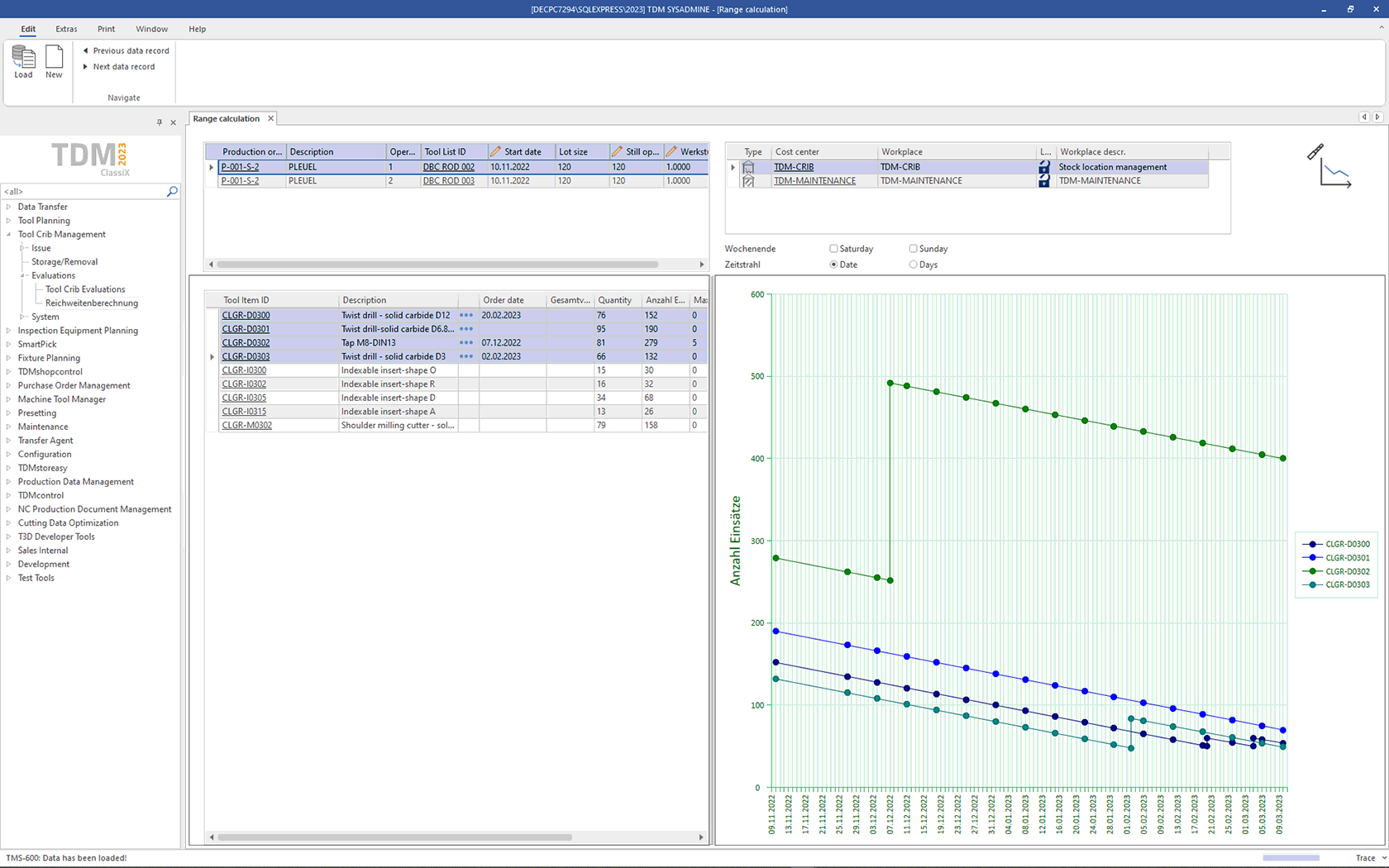

Identifying challenges and trends, and developing a practical solution accordingly – skills like these characterize our expert teams. And they have made TDM ClassiX the most successful tool management solution on the market. This includes innovations that provide direct support to users during certain processes, thereby increasing productivity significantly. In recent years, these innovations have included the TDM Collision Data Generator, the TDM Feeds & Speeds Manager and most recently the TDM Range Calculator. These modules evolved from the requirements of our customers and are now invaluable solutions that are available to all users.

Data that's worth its weight in gold: Unique solutions for efficient data management

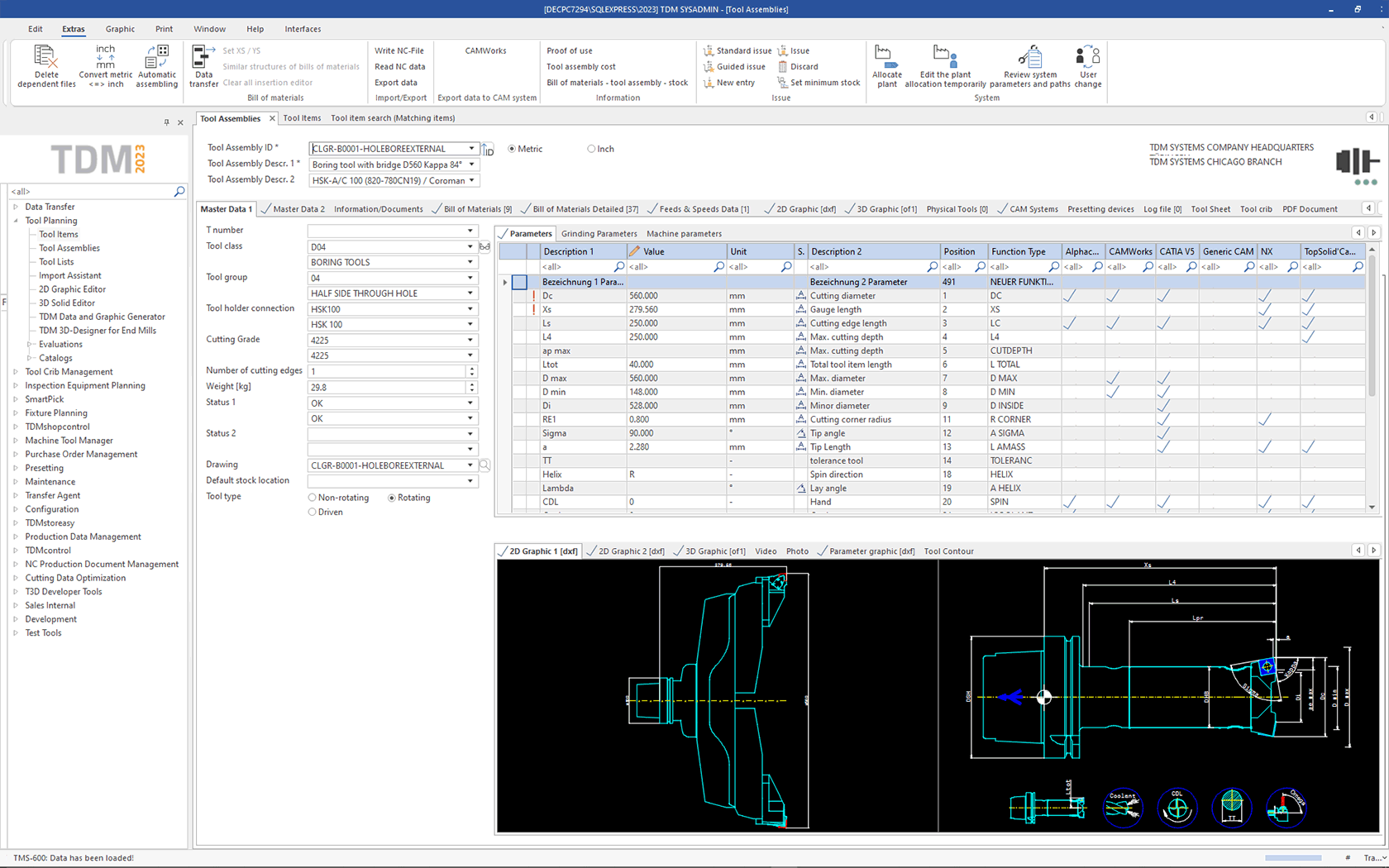

Without valid data, even the very best tool management solution on the market would not provide any advantages. But TDM ClassiX offers comprehensive options for efficient data generation and maintenance. The TDM Data and Graphic Generators are our pioneering solutions to generate and create data records with exceptional data and graphics quality.

TDM ClassiX also offers (alongside TDM Global Line) a range of editors with which the tool data and graphics can be modified and adjusted in TDM using CAD functions. The maintenance of collision and cutting data has also been continually developed in TDM ClassiX. Besides TDM Global Line, it is the only system on the market today that allows you to view and maintain tool data for the requirements of different CAM systems in a single overview (software mask). Users can rest assured: In TDM ClassiX, the entire range of tool data is reproduced and a complete digital twin of a tool assembly can be used.

Comprehensive range of modules: Manage and monitor all production equipment in a single system

TDM ClassiX offers a multitude of software modules that enable users to manage the entire range of their production equipment. In addition to tools, they can also use it to monitor and coordinate the use of their measuring and inspection equipment, fixtures, and NC programs. All production equipment is digitally mapped and organized in a transparent way. But not only that. They can also see the condition of individual items of production equipment. Thanks to this transparency, users of TDM ClassiX can gather all the equipment needed for a production order and bring everything to the machine at the same time. In other words: TDM ClassiX minimizes the risk of production downtimes caused by missing tools or measuring and inspection equipment.

Flexible adjustments: Even better with few adjustments

Sometimes the standard scope does not match 100% with the established processes. Or the system requires further expansions to achieve an optimum degree of utilization with the software. The pre-sales consultancy team at TDM records your requirements and uses them to create a concept which is then implemented by the Custom Development division. We can therefore customize the software to even better adapt to your challenges. Our teams have a wealth of expertise in process design, development, engineering and project management which sets us apart in the market – and which our customers greatly appreciate.

The best of both worlds

Our TDM ClassiX and TDM Global Line software lines can be combined with each other and can be used as a hybrid application. This enables TDM customers to expand TDM ClassiX with Global Line modules step by step. And it allows them a smart entry into the world of TDM Global Line. This way they can take targeted advantage of the benefits associated with this line – such as global performance, the TDM Shopfloor Manager module and even mobile working.