Our data experts digitize your tool inventory

For new customers: Getting started with the right tool master data

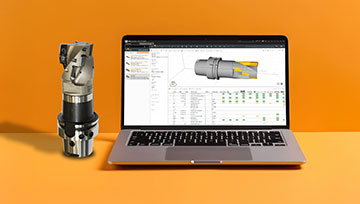

The first step towards digital tool management is the digitization of tool data. During onboarding, tools must be created in a structured manner, classified and enriched with 2D drawings and 3D tool graphics. They often lack the internal capacity or the know-how about tools and data structures. In practice, the existing information is often only available in the form of catalogs or PDF data sheets – but a modern tool database requires standardized, digital master data that also meets the requirements of CAM and simulation systems.

Our Data Service team will support you:

- We create complete component data and tool assemblies

- Missing 2D drawings and 3D tool graphics are created

- The data structure is created in such a way that it can be used directly in your CAM and simulation systems

- We take care of data preparation and support you in the onboarding process with TDM

Ensuring that you can use your TDM software productively from day one.

For existing customers: Targeted improvement of data quality

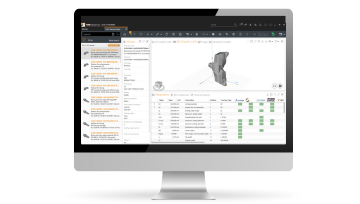

Even for companies that have been working with TDM for a long time, data maintenance is a regular task. Incomplete data sets, inconsistent classifications or missing geometries make everyday use difficult. This becomes clear at the latest when a new CAM system is introduced or integrated into production simulations: It is time to digitize the tool data sustainably and adapt it to the new requirements.

This is where we come in with our data optimization

Well-maintained tool master data is the basis of any efficient tool management system. Our experts analyze your existing tool database and optimize it in the right places:

- Existing master data is analyzed

- Classifications are standardized, gaps are closed

- Data is adapted to new system requirements

- If required, we can also migrate data from external systems

This turns your existing database into a stable and powerful foundation.

Personal advice instead of standard solutions

Every manufacturing company is unique – and so is every tool inventory. That is why we advise you individually: Which data sources are useful? What parameters do your CAM systems need? And how can existing information be transferred efficiently? Together, we will develop your tailor-made digitalization strategy – for efficient TDM Tool Management.

Benefit from the know-how of the data experts

A perfect database is the key to automation, efficiency and productivity. Our experts will support you.

- Easy entry into tool management with TDM

- Reducing the workload of your specialist departments – we take care of the data work

- Consistent CAM and simulation-compatible data quality

- Digital twins for NC programming and simulation

- Fully exploit the potential of your tool database