Our Data Service for tool manufacturers and dealers

Digitization has also fundamentally changed the world of cutting tools . Today, more and more customers expect not only high-precision tools, but also digital product data in accordance with DIN 4000 – including 2D drawings, 3D tool models as well as geometry and feeds & speeds. Because only with standardized tool data can processes in CAM programming, simulation or tool management be consistently automated and efficiently designed.

Tool data according to DIN4000 – we digitize your product catalog

Classifying tools and creating standard-compliant tool data is complex – especially when different data standards, systems and customer requirements have to be taken into account. This is exactly where our Data Services come in: We take care of the complete tool data provision for you, according to GTC format, DIN 4000 and ISO 13399 – ideal for your customers and all common systems.

Practical tool data – classified, consistent, with 2D and 3D graphics

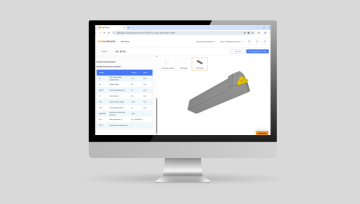

As a manufacturer or retailer, you know how much know-how goes into each of your products. But this knowledge must also be reflected in your digital product data. Technical information such as lengths, chamfers, number of cutting edges or geometries must be recorded precisely, structured in accordance with standards and prepared in full. Only then is CAM programming or simulation with the data possible without any problems.

Lack of capacity or lack of experience in data structuring are often hurdles – we solve this for you. Our experienced team supports you in the standard-compliant creation, testing and output of your tool data – efficiently, practically and exactly according to the current requirements of the industry.

This is how we digitize your tool catalog:

- Recording and optimization: Complete digitization and tool classification including all relevant parameters

- Standardized structuring: Data standardization according to DIN 4000, ISO 13399 and GTC format – 100% compatible

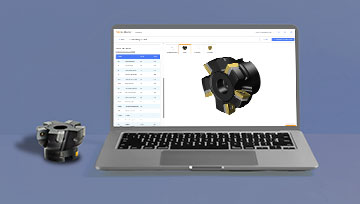

- 2D and 3D visualization: Creation of 2D drawings and 3D tool models for simulation and CAM

- Output in common export formats: Optimized for use in tool management and CAM systems

Provision via your systems – or directly in the TDM WebCatalog

Your digital tool data can be provided flexibly via your online store, ERP or customer portal. This allows you to provide tool data easily – without manual effort for your customers or support teams.

The TDM WebCatalog offers even greater reach. This is where you publish your tools with maximum visibility: Over 390,000 ready-to-use data sets from leading manufacturers make the platform the preferred source for digital product data worldwide.

Your benefits: Become the No. 1 tool supplier – with digital tool data

Our Data Services not only digitize your tools, they also deliver real added value for your customers and increase your attractiveness as a machining partner on the market:

- Tool data according to DIN 4000, ISO 13399 and GTC format – standardized and ready for immediate use

- Smooth integration into CAM, simulation and tool management systems

- Digital presence and availability in the TDM WebCatalog for maximum reach

- Powerful positioning as an innovative tool supplier with digital product data