Digital processes that seamlessly connect tools, data and machines

With the TDM Release 2026, we are taking the next logical step toward consistent digital tool management across the entire shopfloor. A major focus of our roadmap is not only to manage tool data digitally, but also to transfer it automatically and seamlessly to the machine using a standard connection - without interruptions or manual intermediate steps. This maximizes your process reliability with regard to the machine.

In addition, mobile apps enable quick access to data and tasks directly in the machine and tool crib environment. Tools are booked directly to cost centers via barcode, NC programs can be accessed on the go, and the system landscape is even better connected. The result: Increased productivity, reduced downtimes and machines that reach their full potential.

We develop software for you, which is why we are delighted to present the new 2026 release with its most important new features. Here is an overview of the highlights:

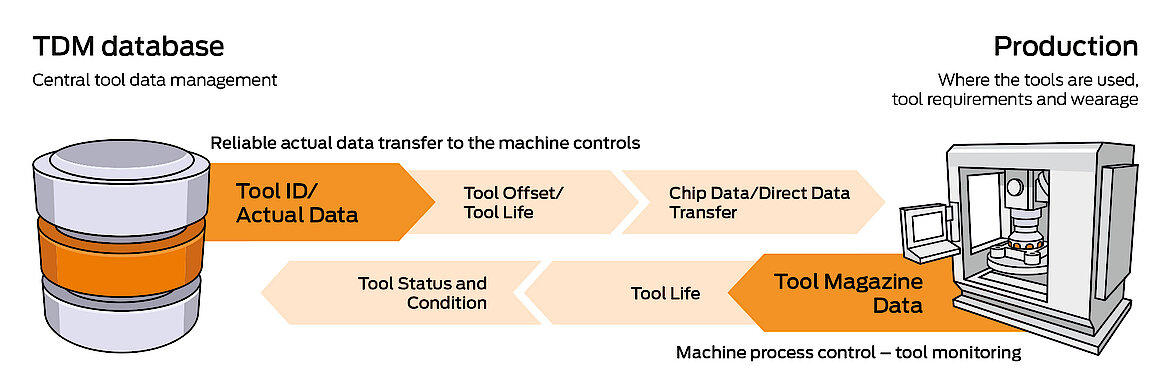

TDM Machine Data Connector interface - connect now in standard machines

The new TDM MDC interface is a TDM innovation and will greatly support and accelerate automation on the shopfloor. With the new standardized machine connection, TDM is directly linked to the most common machine controls on the markets. This means that tool-related information - from master data and (remaining) service life to wear values - flows bidirectionally between TDM and the machine without manual intervention. The result: Complete transparency, forward-looking planning, and significantly higher productivity. And best of all: No individual adjustments are necessary - the interface works as standard!

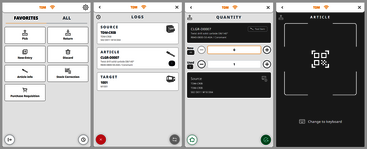

TDM ScanEasy - the mobile barcode scanner solution for the shopfloor

The new version of TDM ScanEasy is now available with significantly simplified workflows for faster and more efficient management of items on the shopfloor. In addition to performing item queries, the main focus is on being able to book tools on the go in any situation. All warehouse processes as well as inventory and quantity postings are supported. Booking takes place directly at the workplace or at the machine: Mobile, direct, time-saving. The new dynamic search function displays suitable item suggestions for selection after entering just a few letters.

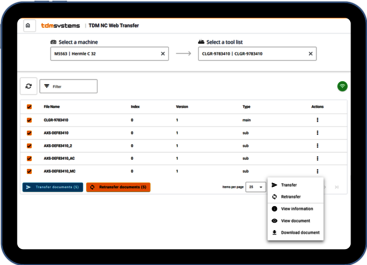

TDM NC Web Transfer - mobile provision of NC programs

TDM NC Web Transfer is a new feature in TDM NC Program Manager. As networks in the production environment are often not connected to the planning area, the new TDM NC Web Transfer now enables mobile, browser-based provision of approved NC programs.

These can, for example, be made available for further use in machine-related directories or, after optimization, be transmitted back to the machine. This saves time, creates greater transparency in NC program handling in the machine environment and greatly increases the usability of the TDM NC Program Manager.

Improved gauge and calibration equipment management: Exchange data with external calibration systems now

The calibration and testing of gauge and calibration equipment is often carried out by external service providers. Previously, calibration and measurement data were not available to users of the TDM Gauge and Calibration Equipment Control Module once calibration was complete. Users can now optimize this process and their gauge and calibration equipment management by transferring calibration data from external systems to TDM Systems. The data is available transparently, directly at the physically managed gauge and calibration equipment - for greater transparency and improved quality management.

CRIBWISE - TDM interface: Seamless data exchange for optimized logistics processes

The biggest USP of TDM Systems is its high level of integrability and connectivity with other systems. TDM can now communicate with the CRIBWISE (Sandvik) logistics system. Essentially, this involves the exchange of tool item data, synchronized stocks, and crib entries. These can be booked in both TDM and CRIBWISE. TDM users can implement automated ordering processes and a transparent tool crib structure for consumable tools by using TDM and CRIBWISE. Synchronization ensures that both systems are always up-to-date.

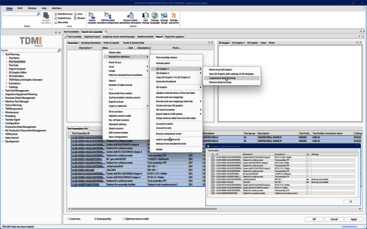

Optimized data management - better options for mass data

The 2026 release offers comprehensive new features for data acquisition and maintenance, especially for TDM tool administrators. The focus is on the efficient processing of mainly mass data, both for items and tool assemblies:

- Conversion from inches to metric and vice versa

- Automatic collision data generation for large amounts of data

- Deleting graphics or data in specific fields

- Optimized measurement of graphics (parameter data)

- Simplified tool assembly of complex tools