Tool management connects

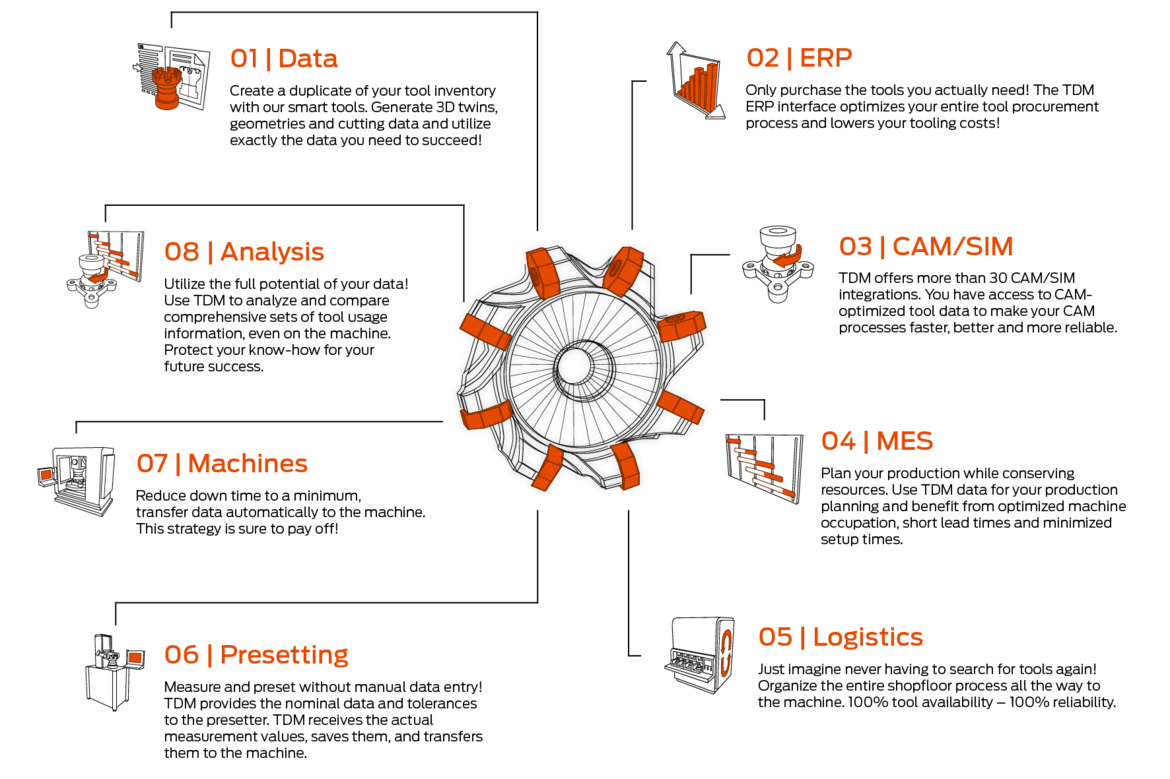

The TDM software solutions organize and integrate tool data in all phases of planning and production. They represent the link between ERP, PLM, and MES. Firstly, they record the master data in a central database. TDM makes the information on items and tool assemblies, including 2D drawings and 3D graphics, available for CAM and simulation systems. Secondly, the software physically organizes tool circulation at shopfloor level. It thereby establishes the necessary transparency regarding tool inventories, as well as the condition and current location of tools. This is the only way to secure optimum demand planning and reduce costs.

Everyone benefits - small businesses, mid-sized companies or international corporations

Tool management is not a question of size. It lays the cornerstone for digitalization and greater productivity at all machining enterprises. TDM Systems supports its customers in selecting and implementing the right solution – whether for a manufacturing hall with just a few machines or networked plants around the world. TDM applications are scalable, grow with you, and can be repeatedly adapted to meet current circumstances.

In-depth tool know-how within our tool management software

TDM Systems is the only software provider worldwide that exclusively develops solutions for managing tool data – an area it has been developing for 35 years.

Another unique selling point: Only TDM Systems prepares the tool data in a requirements-based way for all standard CAD/CAM and NC systems.

As a wholly-owned subsidiary of the Sandvik Group, the company also benefits from its proximity to leading tool manufacturers. Field-proven solutions and interfaces with excellent benefits for users are produced in numerous cooperations with machine and tool manufacturers, software companies, as well as customers.

Tool management offers many benefits, all of which can be achieved with the TDM solution. See for yourself and learn more about why efficient tool management is essential.