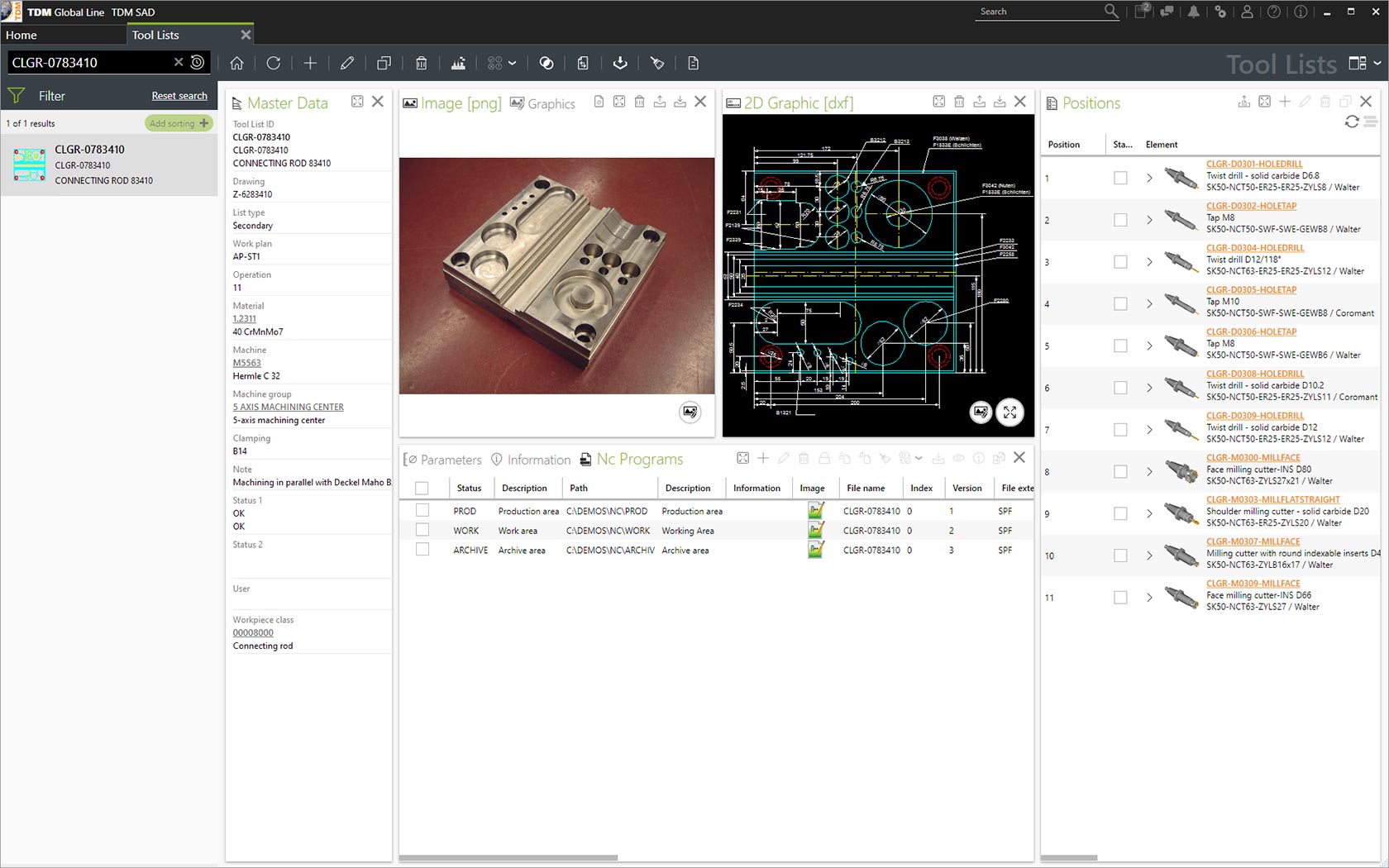

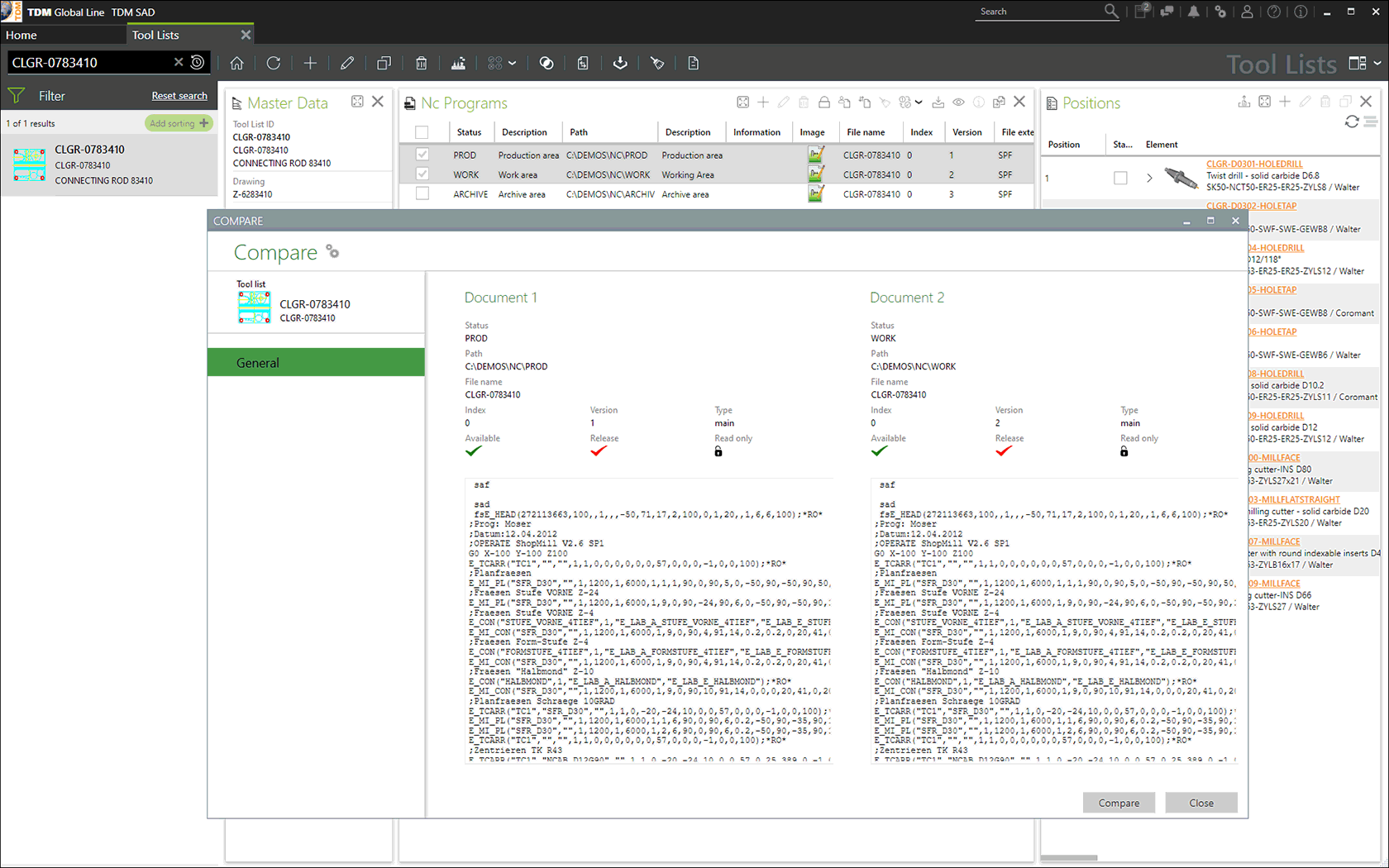

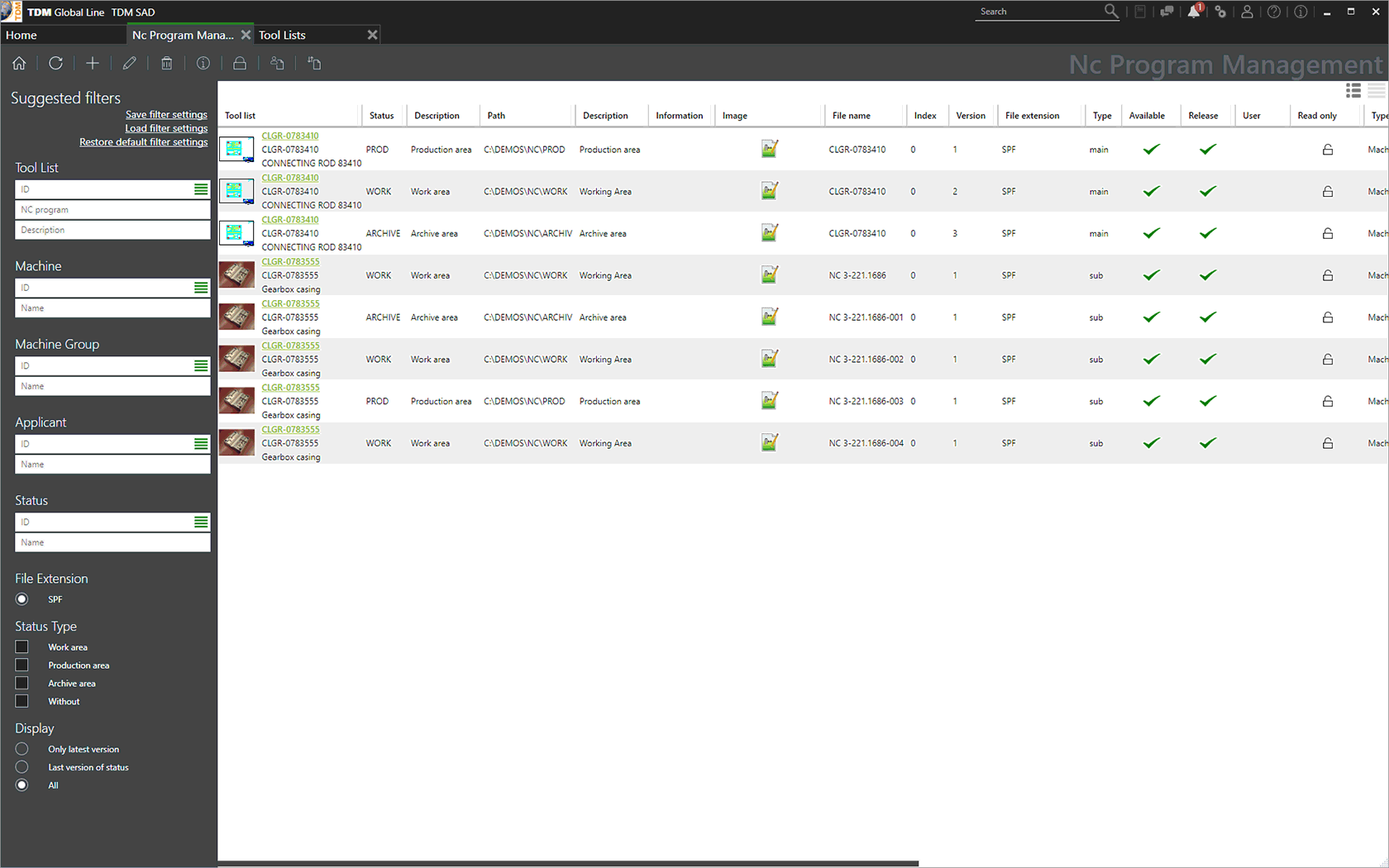

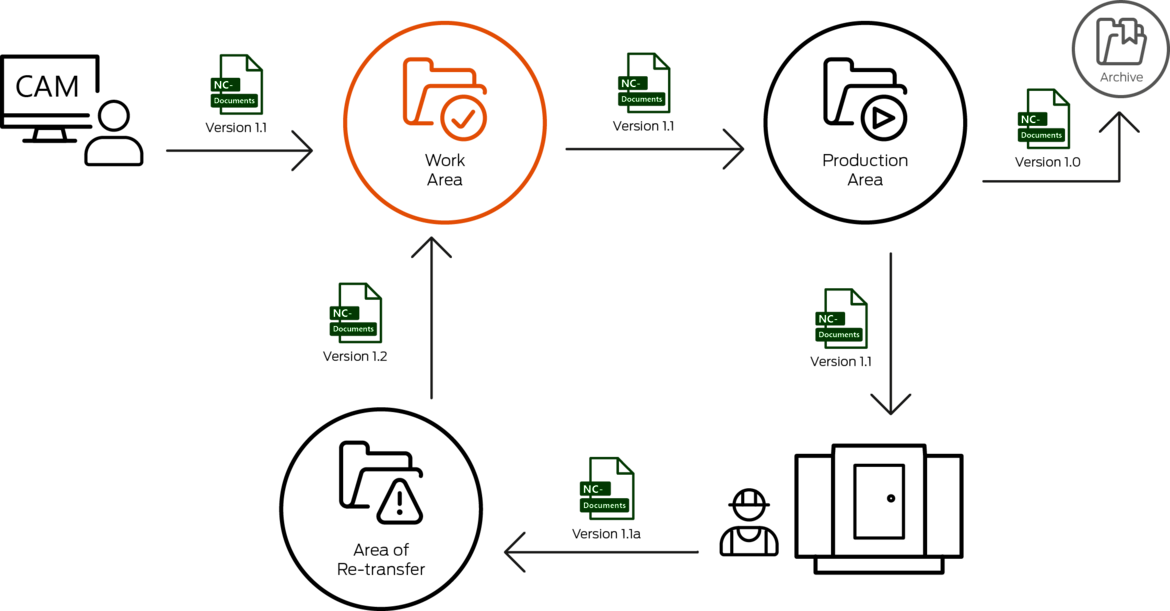

NC program management supports clear processes and seamless documentation

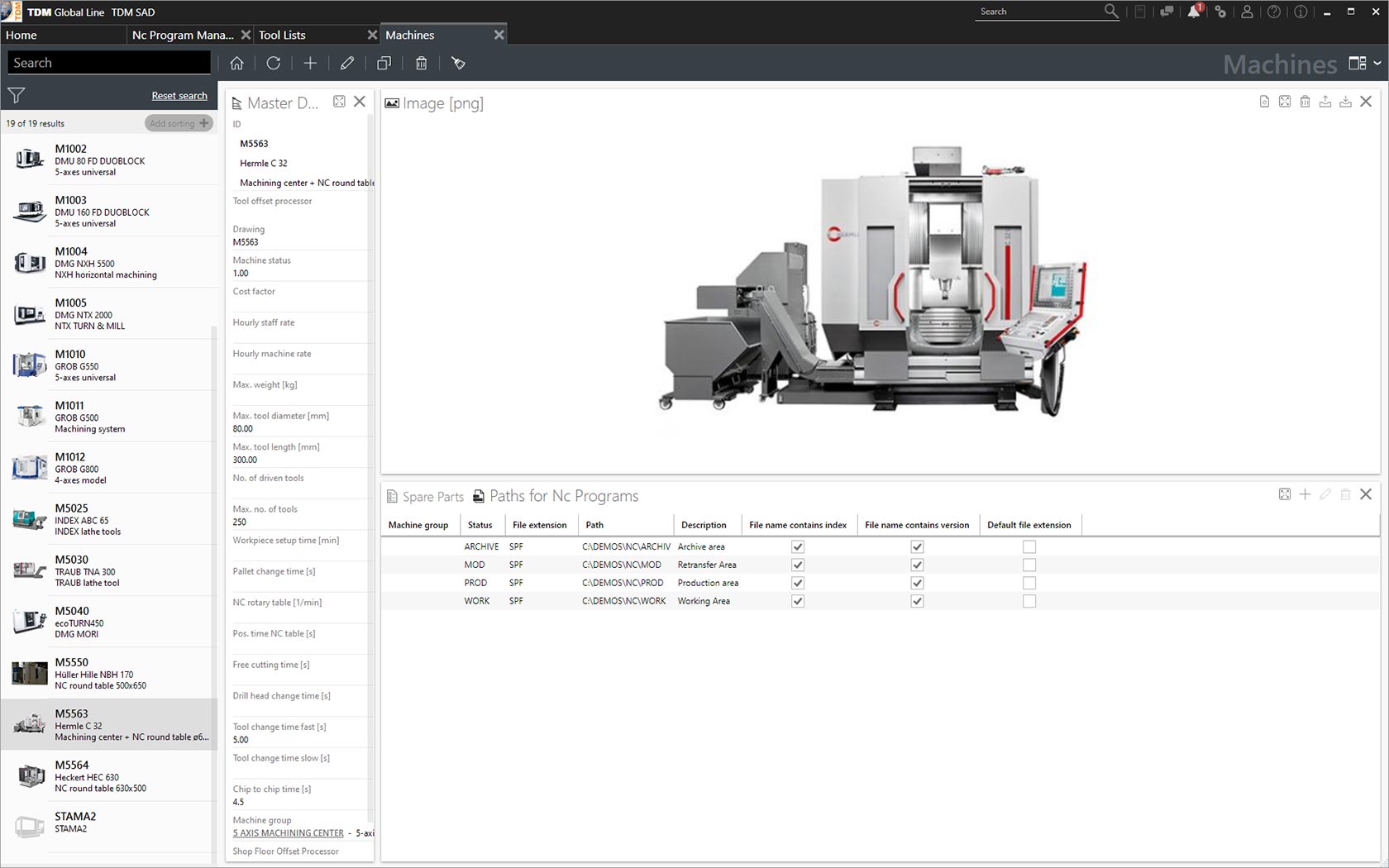

With TDM Integrated NC-Program Manager, you organize all NC documents required in the planning and production environment and realize seamless documentation of component production - starting from the NC documents. NC program management is not just about the comprehensive NC files, tool lists or, for example, fixture plans are also taken into account. The clear assignment of component, NC program and tool list increases transparency and enables the traceability of the production of each component. Clear structures, processes and responsibilities minimize errors and ensure clarity, also with regard to the release process and archiving. The TDM Integrated NC Program Manager ensures access to successfully run NC programs and secures the company's machining know-how.