Reduce both tool crib costs and crib inventories with our tool crib management system

TDM organizes your crib inventories, and thereby your crib costs, economically and with optimum structures. It keeps track of all movements and thereby guides you securely through the tool cycle in production. The module is an important basic function in the holistic Tool Lifecycle Management process. It records the inventories of tools and production equipment.

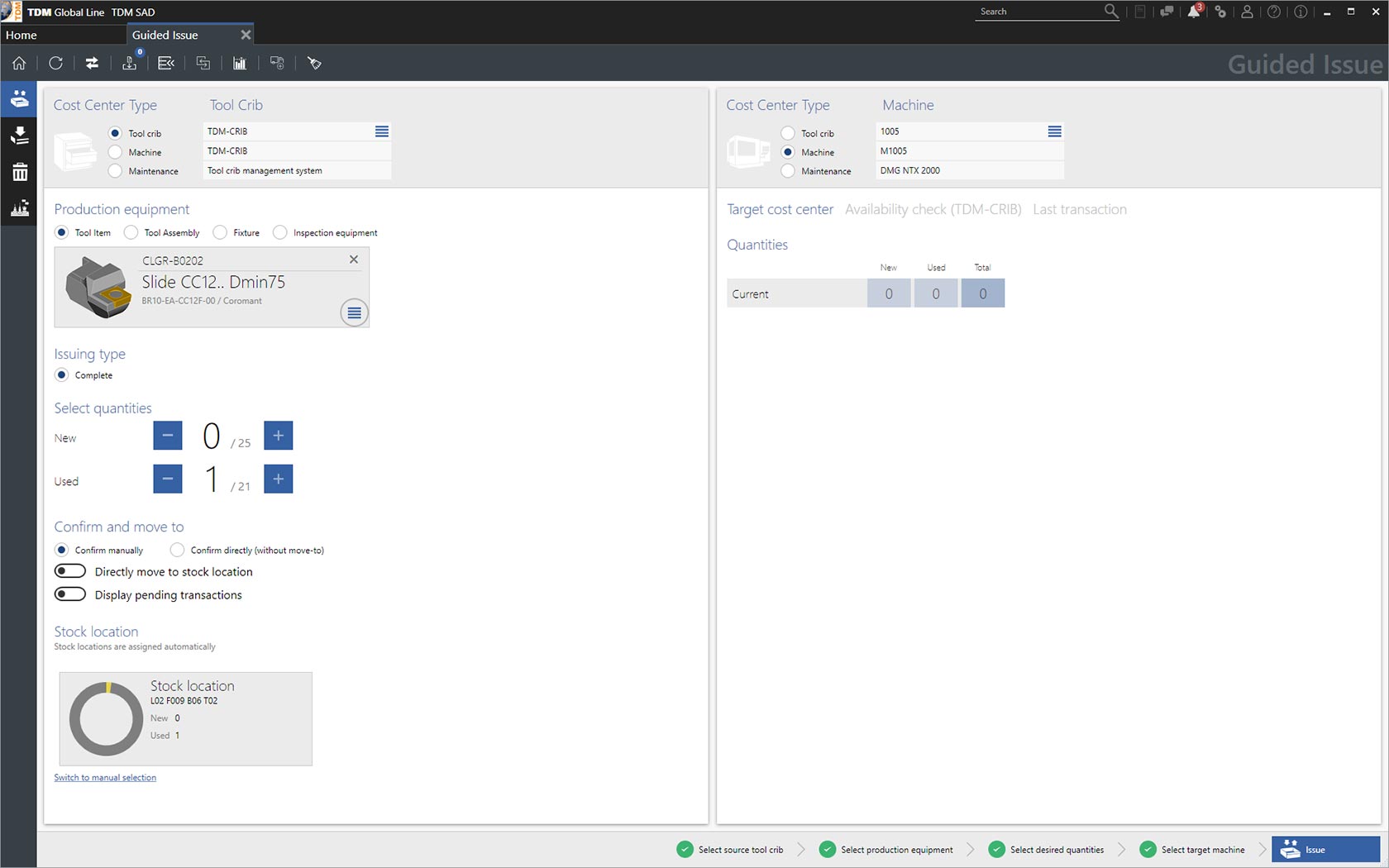

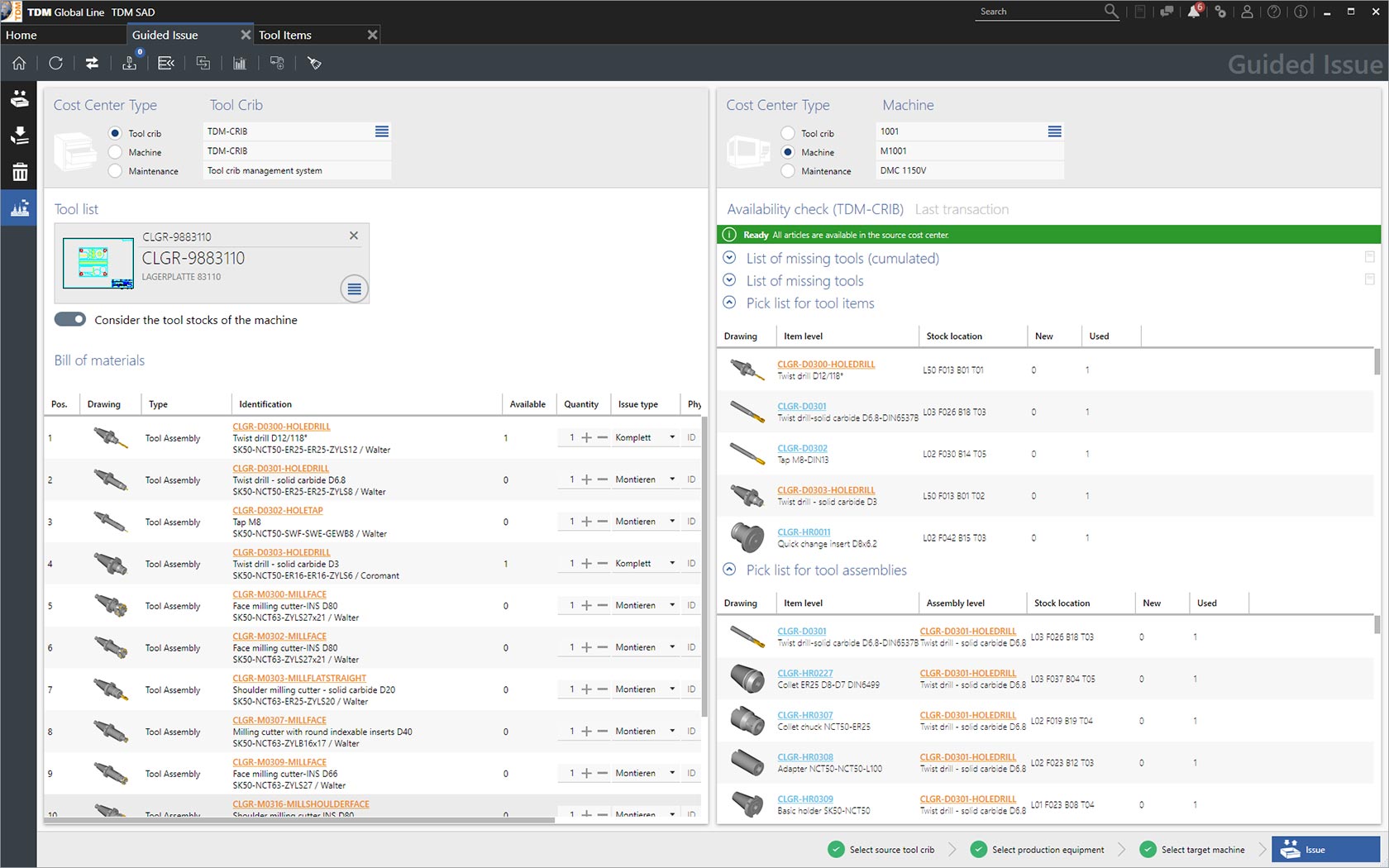

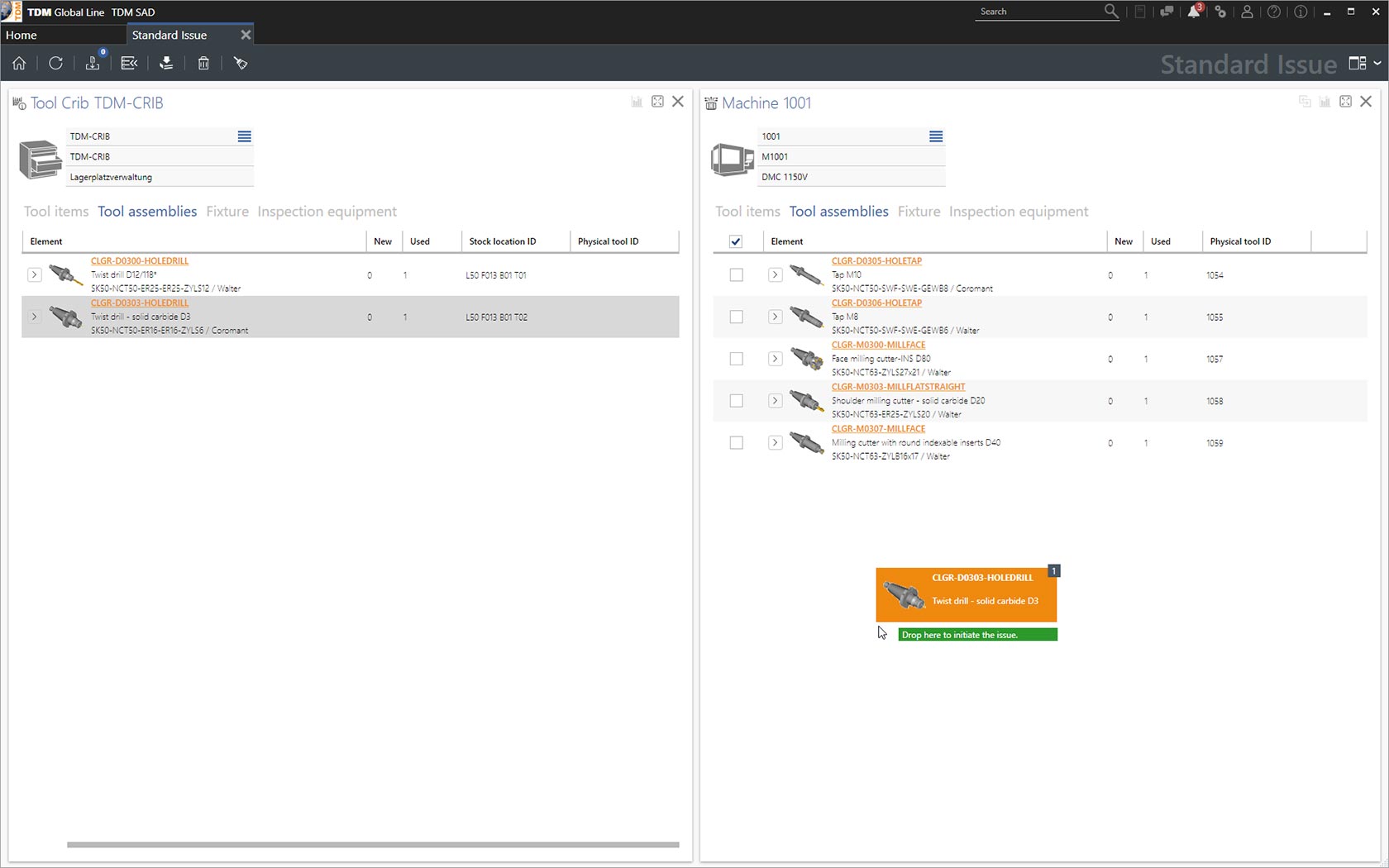

The Tool Crib Module also processes information on their condition and location. This combination creates a solid basis for planning the tools, orders, and machine occupation. The software supports ordering processes, controls and manages automated and manual crib systems, and ensures optimum crib inventory levels. The right tool in the right location thus becomes a reality. Your inventory management and your production productivity will be on point.

Efficient management of crib inventories helps reducing tool crib costs

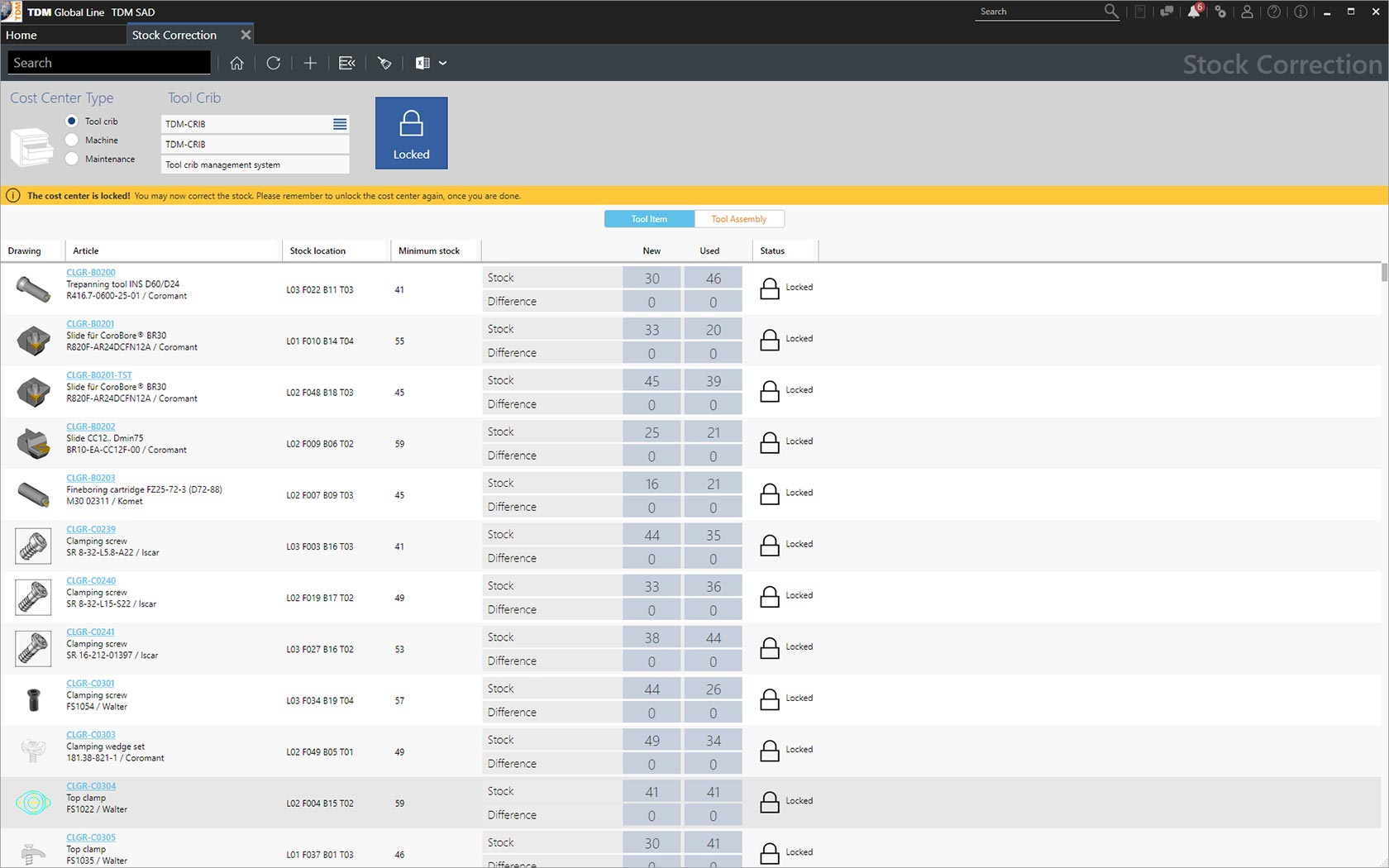

The TDM Tool Crib Module organizes items and tool assemblies by inventory and crib location, taking into account the current location of the tool. This creates absolute transparency and economic efficiency for your tool organization. The software can be used with both manual and automatic crib systems. Barcode scanners are supported for reliable tool identification. This means flexible structures.

The purpose of the module is reducing efforts for logistics, reducing tool crib costs and supplying production equipment. At the same time, efficient storage increases tool availability on the machine.

Clearly structured control made easy with our tool crib management system

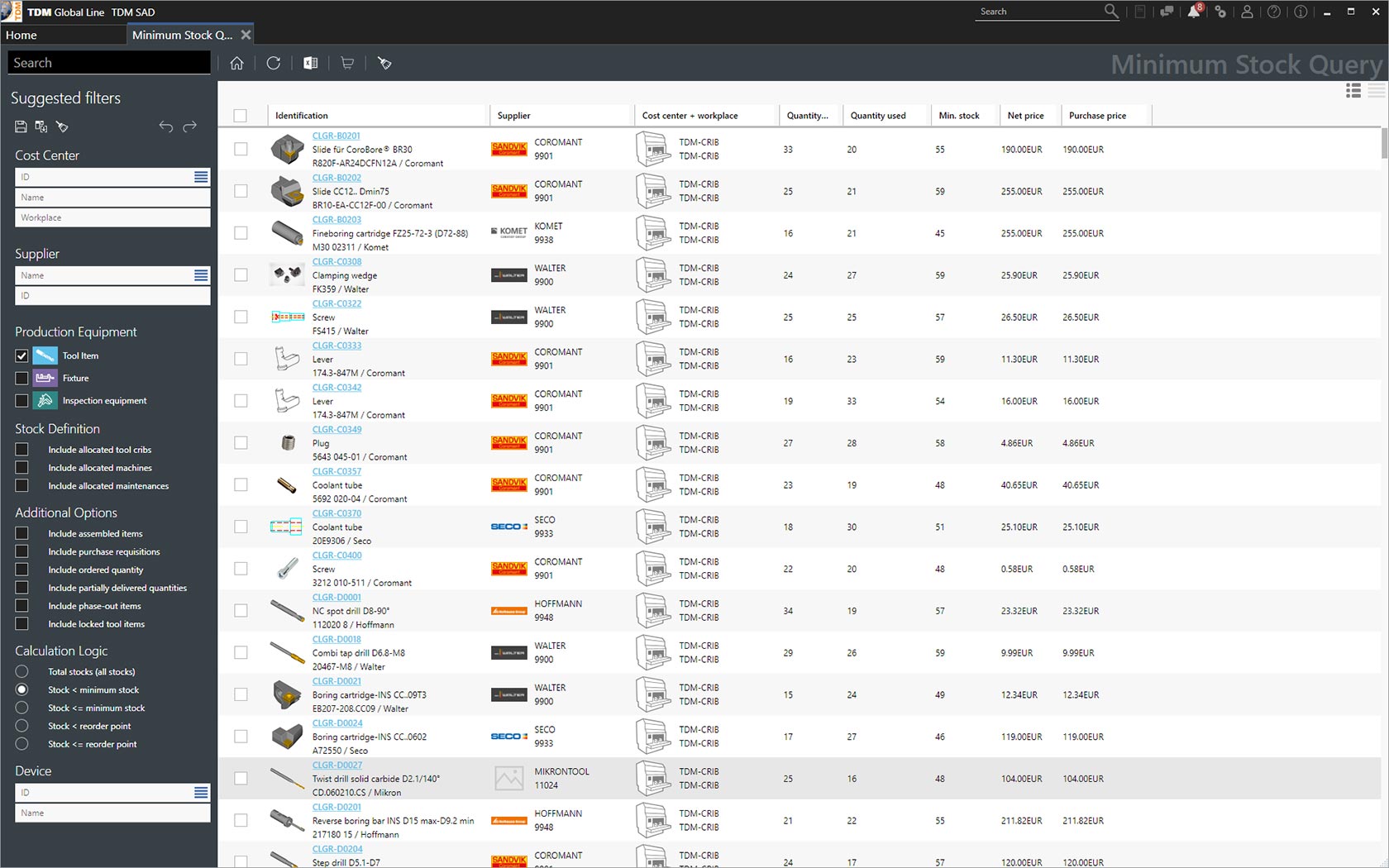

The TDM crib facilitates clearly structured and cost-conscious control of the entire flow of production equipment. The intuitive minimum stock check facilitates prompt order management. The availability check reduces tool-related machine downtimes to a minimum.

The module offers intelligent analyses for optimum inventories. Users can also maintain an overview of tool usage with the informative evaluations. This makes overstocking a thing of the past.