Standardized machine communication with CNC controls

The TDM Machine Data Connector interface connects TDM directly to common machine controls on the shopfloor. Integration works as standard and can be easily incorporated into existing systems and machines.

Integration without adjustment effort

The interface works in standard mode without customer-specific programming. Integrated standard mapping ensures quick commissioning; no individual adjustments are necessary.

Overview of supported controls

- Heidenhain controls (available)

- Siemens controls (from release 2026.02)

- FANUC controls (from release 2026.02)

This form of machine integration creates a stable basis for connecting systems, machines and the shopfloor.

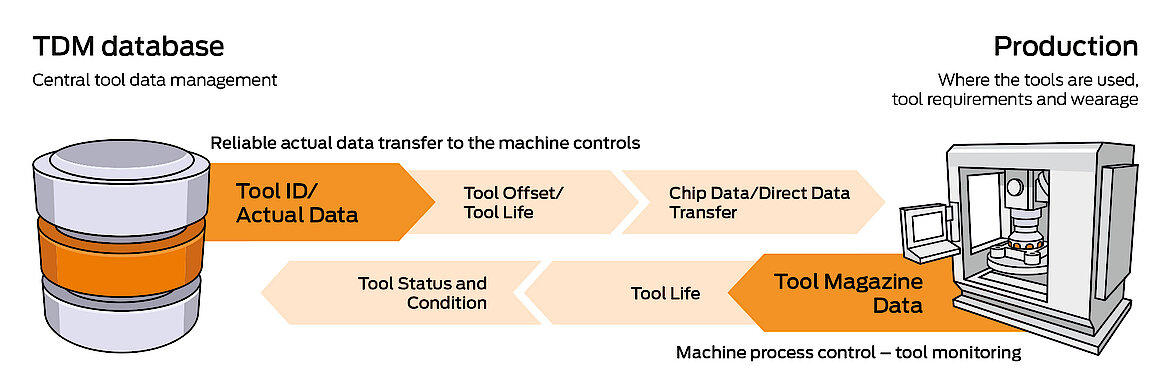

The TDM Machine Data Connector supports two key use cases for machine communication:

1. Reliable data transmission

Measured values and tool offsets are transferred directly from TDM to the machine control system. Integration prevents media discontinuity and reduces errors on the machine.

Your advantages in the process

- No manual data input

- High process reliability

- Uniform database in the system

2. Continuous tool monitoring

Machines automatically send magazine, status, and remaining service life data back to TDM. The shopfloor receives up-to-date information about the tool status at all times.

Increased transparency on the shopfloor

- Current tool statuses in real time

- Reliable planning of tool changes

- Optimized use of machines and equipment

Expert knowledge for industrial machine integration

The TDM Machine Data Connector combines the expertise of our machine data experts in a scalable standard solution. The result is a stable, future-proof machine integration for industrial applications.

Components of the integration

- TDM database as a central system

- Web service for the machine connection

- Application server for communication with the control

This structure enables secure networking of machines, systems, and processes along the supply chain.

An example of a successful implementation of bidirectional tool data transfer between TDM and the machine control system is the Toolfilter interface solution in cooperation with DMG MORI. For this purpose, DMG MORI has extended its self-developed software application known as "Toolfilter" to query the TDM tool data via a TDM Webservice API and transfer it directly to the machine control system. In addition, tool conditions and the machine's tool data are fed back from the machine control system to the TDM database. The TDM – DMG MORI data exchange is based on three main functions:

Tool order request

"Toolfilter" records the missing tools for an NC program allocated to the machine pallet by checking the available tools in the machine magazine. These tool requirements are displayed on the control system and reported to TDM via the interface. TDM takes the tool request into the pick list and creates the presetting order.

Tool data transfer

The measured tools are inventoried by the unique holder ID (Data Matrix Code, RFID Chip ID). TDM manages the individual tool data record for the unique tool identification (holder ID). When the tool is inserted into the machine, the Toolfilter software scans this ID and uses the unique holder ID to request the data from TDM. TDM transfers all tool data to exactly the requested tool and Toolfilter writes it directly into the machine control system's tool data management.

Tool data report

If the tool is in use in the machine control system, Toolfilter reports the current tool information, such as condition, wear and remaining tool life, back to TDM. In TDM, this tool report displays the machine's tool magazine and visualizes the tools' current situation in the TDM application. This enables the provision of replacement tools, or the missing tool, for subsequent machining without interrupting production.