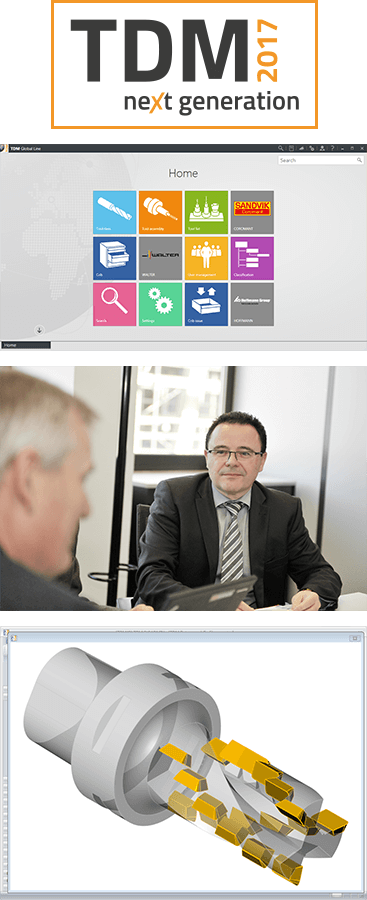

TDM next generation will be the state-of-the-art, highly evolved platform which will be capable of handling the operation of all existing TDM modules as well as TDM Global Line modules simultaneously. It now allows customers to completely overhaul and update their TDM software without a complicated system change. The conversion from the previous 2-tier architecture to today's 3-tier architecture will increase both performance and process reliability while simultaneously reducing installation and service effort. Additional advantages will include simplified interface handling, easy use of on-demand and browser-based solutions and the combined use of standard and engineering solutions. The customers will find a solution tailored to their individual needs.

Safeguards in place for investments in previous applications

In talking about the benefits of TDM next generation, Eugen Bollinger, Sales Manager at TDM Systems, says, "Switching to TDM next generation provides customers with a complete modernization of their TDM-system with the least possible time and expense. The new architecture makes its applications perform better, both locally and across plants, and more fit for the future." Bollinger also emphasizes, "We're always focused on the customer, so we place special importance on ensuring that our customers' investments are secure and that they can continue to use the modules they have. And we simply couldn't be more excited about the new features in our software."

At AMB 2016, which will take place in Stuttgart from September 13 to 17, 2016, TDM Systems will introduce TDM next generation at the booths of its partners, Walter AG (Hall 1, Booth G32), Seco Tools (Hall 2, Booth C04) and Sandvik Coromant (Hall 1, Booth E52).

At IMTS 2016, which will take place in Chicago from September 12 to 17, 2016, TDM Systems will feature TDM next generation at its own booth (E-3264) and at the booths of Walter USA (W-1700) and Parlec Inc. (W-2300).

Additional information about the new software generation:

- First-class graphical 3D tool assembling

- TDMsearch: The new innovative standard for tool searches

- TDMcheck: Analyses data and processes in TDM and suggests potential improvements

- Intelligent data concept: New data can be imported independently of the software version, ensuring maximum flexibility

- TDMimport: Targeted, automated import of tool data from a variety of sources, possible both from external systems and from legacy databases

- Press release English (docx)

- Press release German (docx)