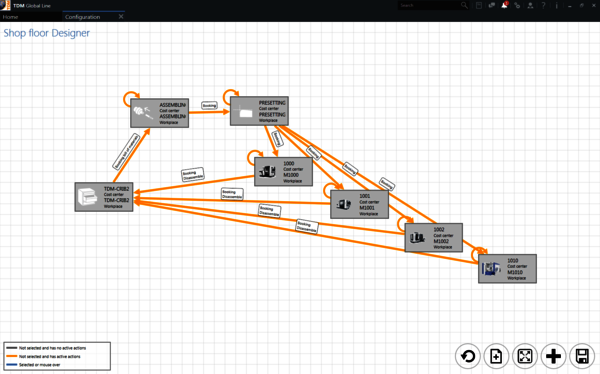

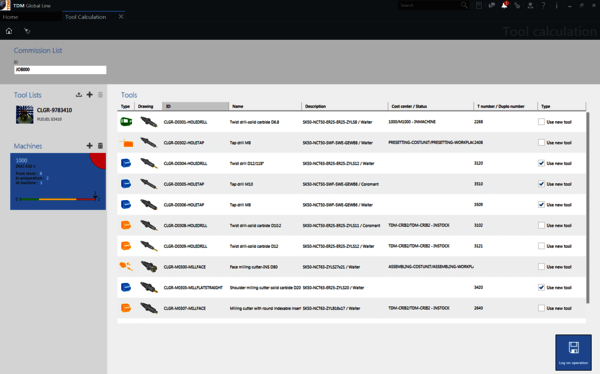

"With the TDM Shopfloor Manager in TDM Global Line, the customer can use a configurator to individually compile all workflows." For Volker Schwegler, Senior Consultant and Product Manager at TDM Systems, this means that the days when a shopfloor had to adapt to rigid software are now in the past. Consistently modular in design, the shopfloor management adapts to all conceivable circumstances in order planning, configuration and the workflow for cribs, assembly, presetting, machine and secondary cribs. The tool list forms the basis for every requirements calculation – "no matter whether we are dealing with orders, individual workpieces or NC programs, in the end, everything is broken down into tool lists".

The user situation is decisive

During development, TDM Systems is always oriented towards each user's respective situation. Every person involved in a process should be able to view the precise information they require for their specific task. Additional guidline: The real tool circulation, which arises from the configuration in question. A crib, a presetting area and a machine are typical, where tasks are assigned to each of these areas. Typical – but not universal. Schwegler: "Many companies combine assembly and presetting together in one tool room, for example. The two areas can be combined in this case to form a cost center – the "tool room" – and all actions can be combined into a single screen."

Everything freely configurable

Thanks to a modular design, the software is freely configurable, without any need to adapt the programming. Schwegler: "It therefore follows the process – it is no longer the other way round." This flexibility also drastically reduces the individual adjustment effort. At least 80 per cent of customer requests can be covered as standard. However, too much flexibility could lead to faults if processes are compiled in the wrong sequence. This prevents an integrated plausibility check, which only permits sensible sequences. "We will soon also only be able to preselect processes that are also sensible, promises Schwegler.

The TDM Shopfloor Manager from TDM is fully compatible with the stock management of the TDM Tool Crib Module Global Line. This means that even tool assemblies in secondary cribs and those near machines can be managed. You can therefore always know precisely where the tool assemblies are and what condition they are in. Disassembling, reassembling and presetting are no longer strictly necessary, saving significant time and costs. "We therefore have the best overview in the tool circulation for each user," Volker Schwegler states with conviction.

- Press release English (docx)

- Press release German (docx)