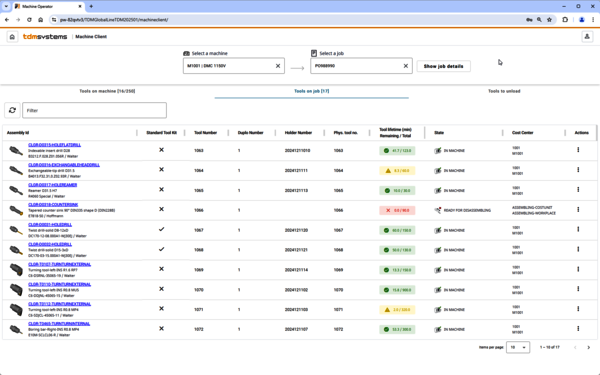

The new TDM Machine Web Client is a powerful and intuitive application designed to help machine operators to manage and monitor tools on the shopfloor more effectively. With its user-friendly browser interface, operators can easily access critical information, view tools and jobs, and perform operations more easily. Operators have all relevant machine data for tool management available in real time at a glance, leading to more efficient processes. In addition, the tabular tool overview gives direct access to tool ID, description, T-number, duplo number, holder number and tool life information, and retrieve detailed tool information, including master data, 2D graphics and bill of material.

Toolhive and Cribwise

Toolhive, that premieres at EMO 2025, is a new cloud-based, entry level solution aimed at SMEs and companies new to tool management that want to streamline the tooling inventory process, whereas Cribwise is a dedicated digital tool inventory and order management software, helping customers to get control over their inventory, such as CNC tools, cutting tools, spare parts, small assemblies, consumables, and personal protective equipment.

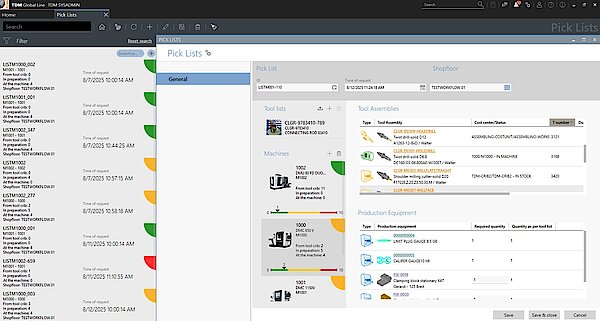

TDM Shopfloor Manager Global Line

At EMO 2025, TDM Systems will also introduce the latest version of the Shopfloor Manager Global Line. This module monitors the entire tool circulation, helps to achieve optimum utilization of tools on the shopfloor and increases production. The visual planning of the production processes guides users through the individual tool circulation stations in a targeted manner, from the tool crib to the machine. This delivers a high degree of transparency in the shopfloor organization of the tools, maximizing the utilization time of the machines. The latest version of Shopfloor Manager now also takes production equipment into account in the tool requirement calculation.#

New: Data Services

TDM Systems’ Data Services digitising tools builds the foundation for efficient, digital tool management with TDM software by bringing greater transparency, control and productivity to the manufacturing process. Whether customers are new to the TDM system or want to optimise their existing tool data management, digital tool data maintenance presents a challenge for many companies. This is exactly where TDM Systems’ services for data preparation, initial data base population and data migration come in.

“Every manufacturing company is unique, and so is every tool inventory,” said Christian Kuebel, Head of Sales EMEA, APAC & Channel Management at TDM Systems. New and existing TDM users often lack the capacity and expertise in tool and data management, even though the correct database setup and structuring is crucial for achieving a good digital tool management system. “That is why we take care of data entry as a new service, both for new and existing customers. This also includes individual advice about the proper data sources, the parameters their CAM systems needs and how existing information can be transferred efficiently,” explains Kuebel the new services. That way the TDM experts are developing a customized digitalization strategy with the customer that gives them the most efficient tool management.

- Press Release English (docx)

- Press Release German (docx)