An interface for enforcing standards

When the Siemens NX CAD/CAM/CAE software was introduced in 2007, GROB also immediately invested in the corresponding TDM interface. According to Stefan Schur, Head of Production Support at GROB, using the FBM (feature-based machining) interface features contributed to "a boost in performance". A feature that accelerates and standardizes the programming. 40 NC programmers at the German site and, in total, approx. 30 NC programmers in the USA, China and Brazil work with NX and FBM today. And, when faced with approx. 30,000 used tool assemblies and approx. 7000 to 8000 material groups with dozens of individual materials and, therefore, several 100,000 selection variants, we "do not always need to reinvent the wheel".

Suitable tools are automatically suggested

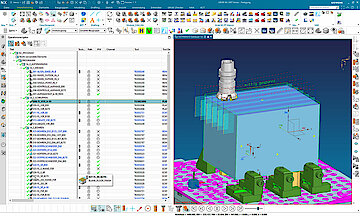

Instead of manually selecting the corresponding tools for each workpiece feature in the database, as was the case previously, these are now automatically suggested to the NC programmer. In addition to avoiding additional costs, this also "guarantees that the machining always meets our high requirements, regardless of the respective programmer," says Schur. At GROB in Mindelheim, an administrator determines in Siemens NX which tool should be used to regularly machine certain features. The program then adds up the tools that meet the predetermined guidelines for all identified features. Exactly those that are already used as standard tools. Only if the existing tools are not sufficient for the machining does Siemens NX request the right tool for the feature in TDM and upload this.

A significant win

GROB has not yet identified concrete figures regarding how the use of the FBM features affects the performance of the NC programmers or the utilization of the machines. However, "we can clearly feel that we are more effective," says Schur. In doing so, it is not only the production of workpieces and the machining precision that has increased in the last three years, according to Schur. The level of trust in the processes has also now become "extremely high". For bore holes, for example, there are no longer any queries – "they are a runaway success". This also means that the machines can now be run in more quickly in the event of a workpiece change. The machine operators simply know that the tools specified by the NC programming do exactly "what they should".

Objectives for introducing and using the TDM-CAM interface to NX

-

Management of hundreds of thousands of selection variants for tools via 30,000 tool assemblies with 7–8 material groups and dozens of individual materials

-

International enforcement of manufacturing standards by centrally allocating tools, technology and machining features

-

Greater performance overall in NC programming

Process innovations

-

Centrally maintained data pool with complete tool data, feeds & speeds and materials

-

Automated tool selection: Allocation of tool assemblies and material groups to the machining features allow for automated creation of tool suggestions with FBM

-

Performance boost in CAM programming: Thanks to automated tool selection and fast data access to large volumes of data (especially internationally)

-

Central definition of shopfloor standards for each individual machining operation; these are passed on to each plant via TDM