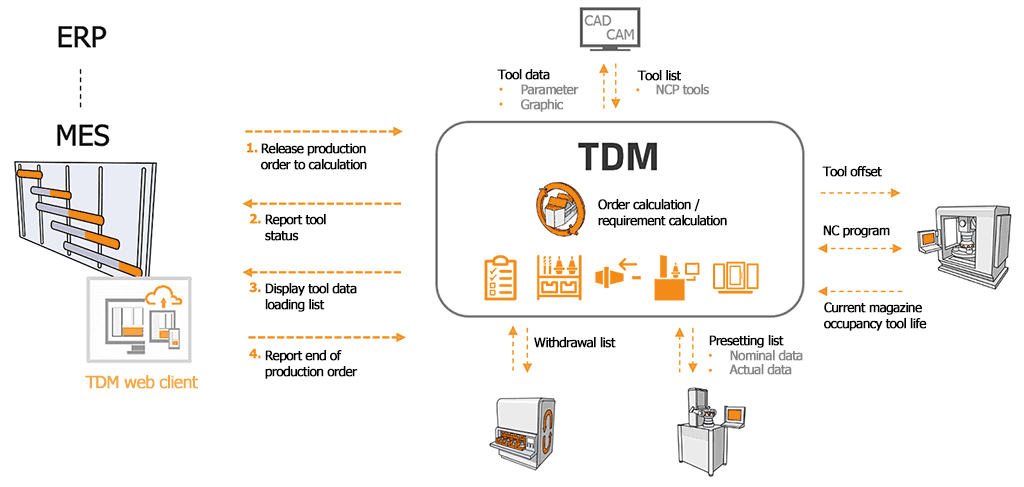

“We are currently seeing a clear digitalization trend among our customers,” says Matthias Gröger, regional sales manager at TDM Systems. “Customers are wishing to further expand digitalization in production, and they want to roll it out towards the machine.” As with the integration of NC planning systems, customers want the organization of tools around the machine to be fully digitalized and optimized to eliminate errors. The development goes a big step further towards Industry 4.0 and aims for a closed data circuit. This means that newly acquired data can flow back into the central database, be saved in the correct place, and be used for further applications. A tremendous advancement.

Tool circulation digitally organized

The calculation initially seems quite simple: The less setup, the lower the effort and costs incurred. Calculating this requires software that visualizes the tooling inventory at the machine. The Shopfloor Manager of TDM Systems compares this with the tool requirements for the next order. With a direct machine connection, this accounting can be done based on the current machine occupation and not only based on the bookings in the system. Gröger recognizes: “In this way, users can see precisely which tools need to be consigned and can keep an eye on the outlay even for small batch sizes.” If remaining tool lives are registered and factored in as well, these can also be streamed into the requirements calculation and make the result even more exact.

Tools uniquely identified

Tool data can reach the machine control system in a variety of ways. To ensure that the data can be clearly assigned to the corresponding tool, unique identification is an absolute must. TDM as an open system supports various technological approaches. One possibility is to identify each tool assembly uniquely with a data matrix code – an inexpensive and simple technology. In TDM, each tool is uniquely identified. The data belonging to a particular tool is therefore assigned without any doubt. For the actual data transfer, a middleware solution is currently still required. By scanning the data matrix codes at the machine, the data is then automatically written to the control. TDM Systems collaborates here with experienced partners but is also working on its own solutions.

Better planning with real tool life data

“Due to the multitude of different machine manufacturers and machine control system vendors, there is currently no generally applicable standard for a machine connection on the market,” explains Gröger. Nevertheless, with the solutions currently available, it is possible to realize bidirectional machine connections. This increases transparency in the planning process tremendously. Just knowing which tools are in use at the machine is only half the challenge. Tool lives can also be factored into the requirements planning of an order and enable an exact calculation. Tool life tracking enables predictive preparation of sister tools. These are ready and waiting at the machine when the tool life expires.

Setup digitally optimized

“For many machinists, the preparation of tools is quite a hitch,” says Gröger. “Even due to the setup process itself, because loading and manual data input at the machine are immensely prone to error.” It is still often the case that machine operators, reading data from paper lists, will enter the data directly into the system by hand. If tool assemblies are identified, for example, by a data matrix code, the data transfer is initiated by the scanning of the code and the data are written to the machine control system automatically. “The setup time is reduced as far as it can be and the error rate drops to zero,” says Gröger, who oversees a number of customer projects with respect to machine connection.

What are the technical possibilities today?

“There are currently various technical possibilities for realizing data communication with machine control systems,” says Gröger. Data transmission can be handled either by a different software application, such as a manufacturing execution system, or by middleware, web services or a direct communication with the software of the machine control systems. TDM Systems currently offers interfaces to the leading manufacturing execution systems, such as Fastems, Soflex, Forcam, RWT, Procam, Certa and others. In addition, TDM Systems works with partners who enable bidirectional data exchange via a middleware solution. Even a direct connection to the software of the machine control system is possible.

Outlook: More TDM at the machine

TDM Systems continues to work on solutions to connect TDM more closely with machines and to enable greater efficiency and convenience in setup operations. Currently, the development team is working on a machine information system that enables the handling of tools around the machine and provides support in setup and teardown operations. Initial customer applications are showing enormous potential and bring greater transparency to machine organization. “If you are now taking your next step towards Industry 4.0 with a direct connection between the machine and your TDM system, our experts will be happy to advise you and drill down into the possibilities in your production shop.”