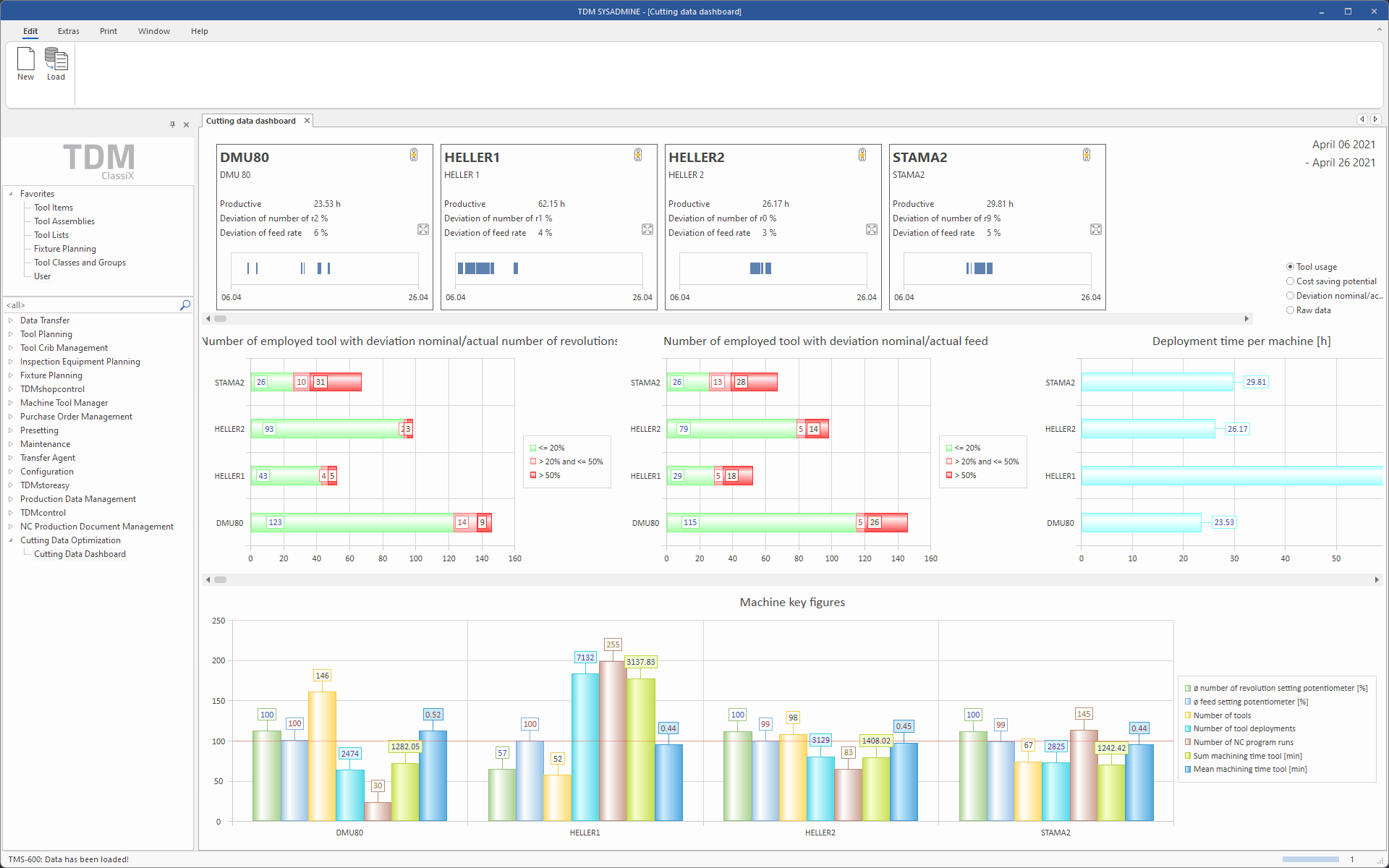

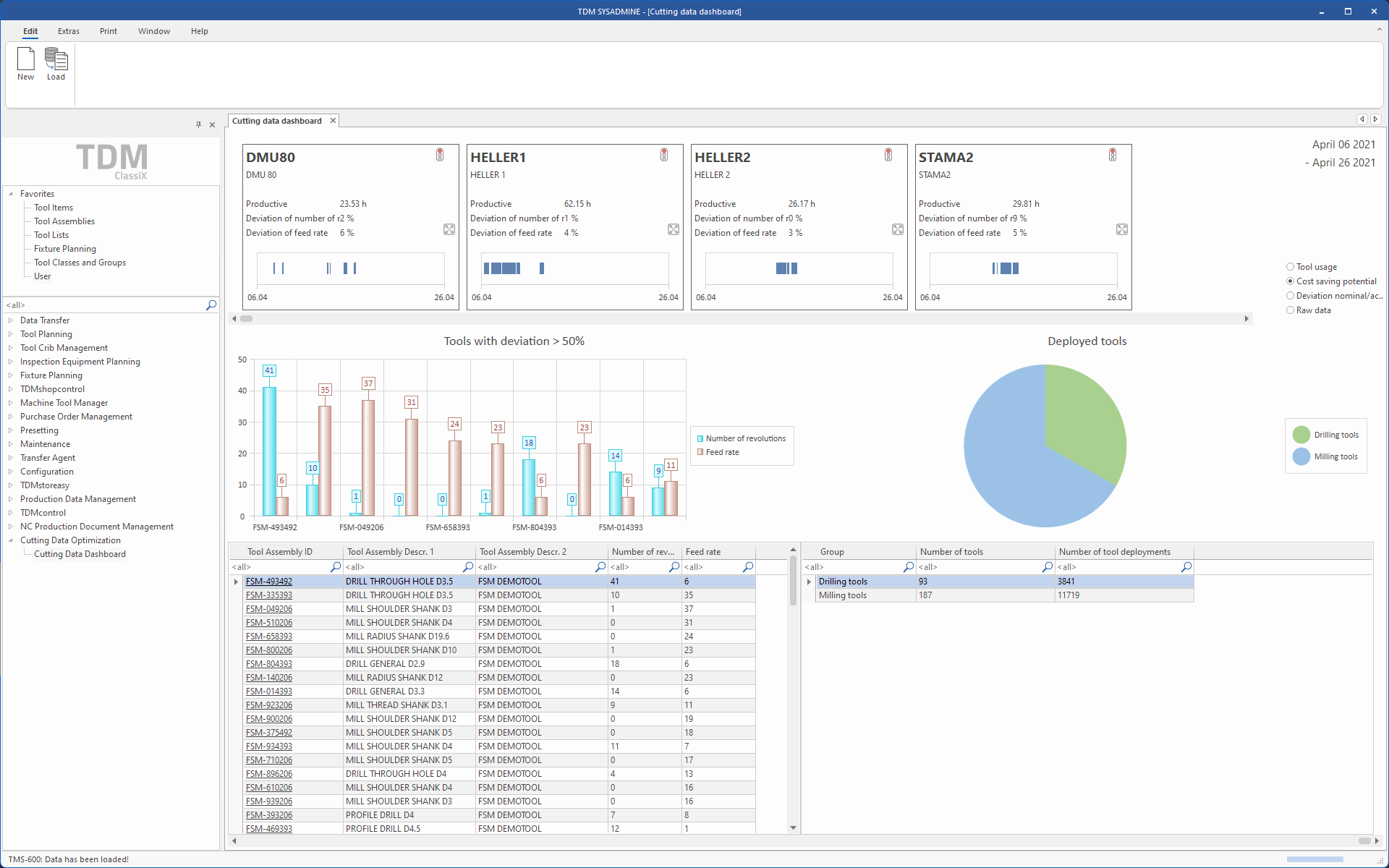

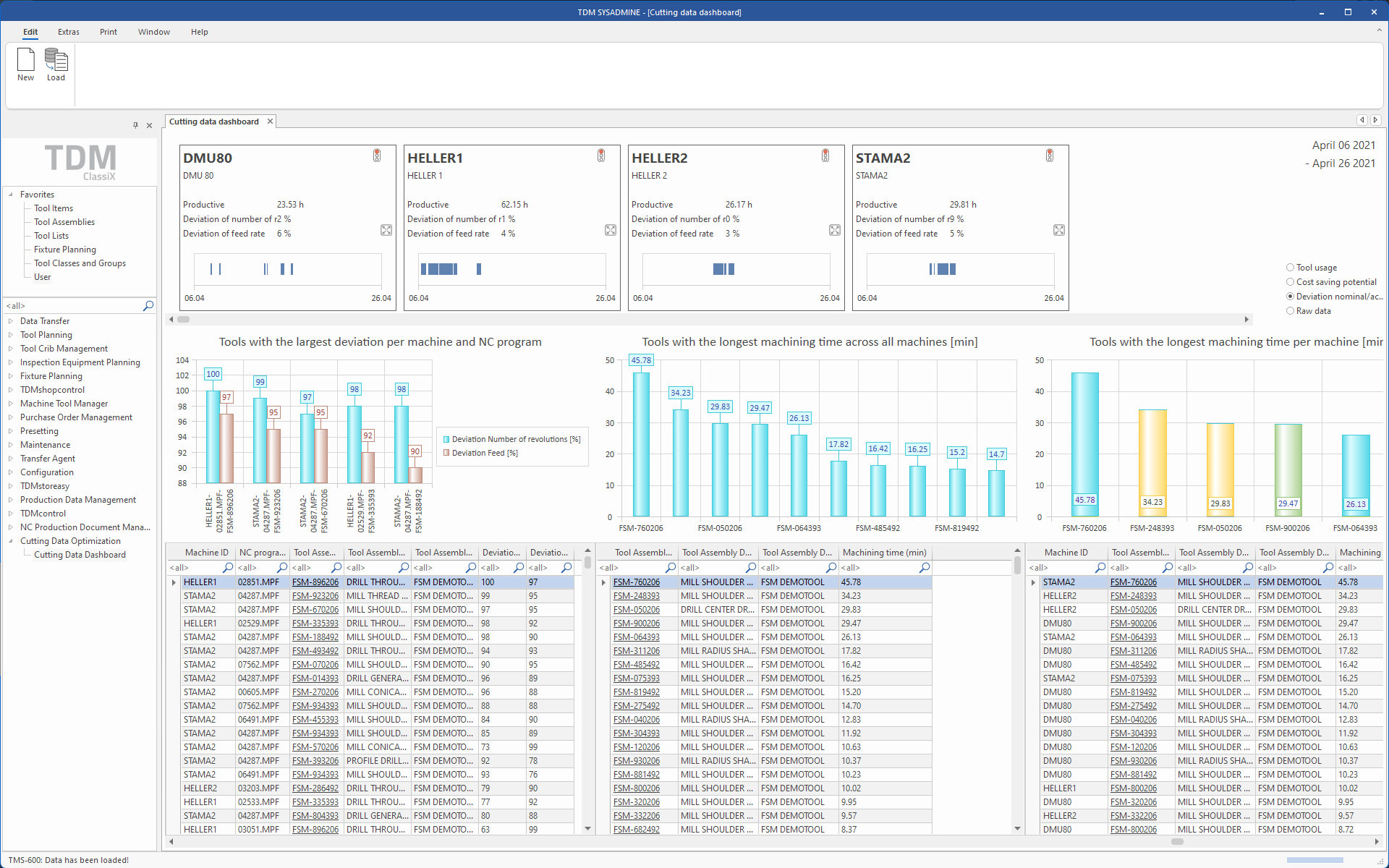

Now possible: automatic feeds and speeds monitoring and data evaluation directly in TDM

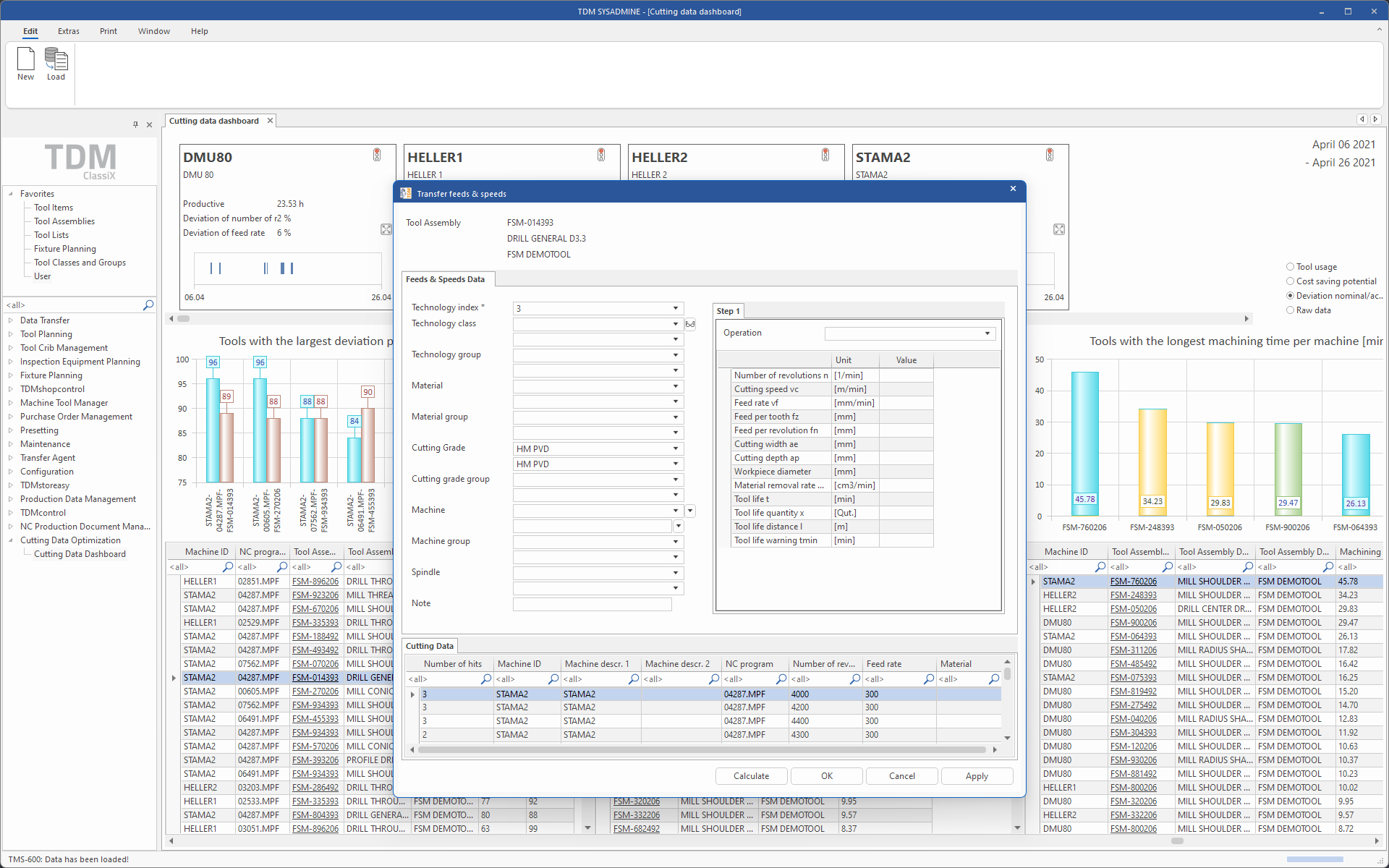

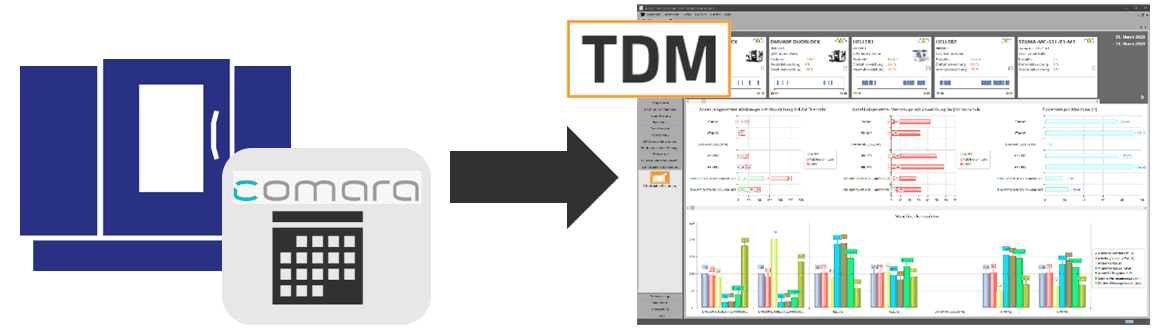

How do you determine your driven cutting data? With TDM Feeds and Speeds Manager you build a standardized verification process of NC programs by evaluating and comparing planned and driven cutting values. The Comara-Box is a standard industrial PC that is connected directly to the machine control via an interface and selects and condenses the tool-specific machine cutting data. Through an interface, the data reaches the TDM database and is evaluated and visualized with the TDM Feeds & Speeds Manager and saved by the user as technology data for the respective complete tool. The Feeds & Speeds Manger is a standard solution that is easy to implement and offers you enormous potential for improvement through the return flow and evaluation of the actual cutting data.