TDM Systems develops software for the management of tool data in the machining area. The company offers solutions and services for the entire tool data lifecycle. Regional Sales Manager Andreas Maier specializes, among other things, in tool logistics: "tool crib storage differs significantly from normal storage management. While screws and gloves hardly ever return to storage, the situation is different with tools. The three most frequent transaction types are:

- Tools that can be reused after use, such as tool holders or adapters

- Worn out tools that are re-conditioned after use, such as solid carbide tools or special tools

- Items that cannot be reused such as inserts or spare parts, for which no more tracing is usually required after their removal

The TDM Tool Crib Module can map any physical storage: "It adjusts to the customer and not the other way around," says Maier. At the same time, it incorporates itself into other systems such as Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES) in the interest of Tool Lifecycle Management. Even if the tools leave the premises for refurbishment, the Tool Crib Module "keeps an eye on them."

Different Crib Systems

First and foremost, tool crib software must be flexible in order to cope with the many different crib systems on the market. Andreas Maier explains: "Essentially, we distinguish computer-supported systems and classic crib cabinets. The former are divided into those with controlled and guided tool removal." According to Maier, guided means that the shelf board moves out of the crib and displays from which area how many units should be removed. Controlled, individual dispensing of tools allows for what is known as vending machines, similar to vending machines for food. Maier continues: "These have experienced a boom in recent years and are used mainly for round-the-clock supply in multi-shift operation." Here, the most important thing is the shortest possible access times.

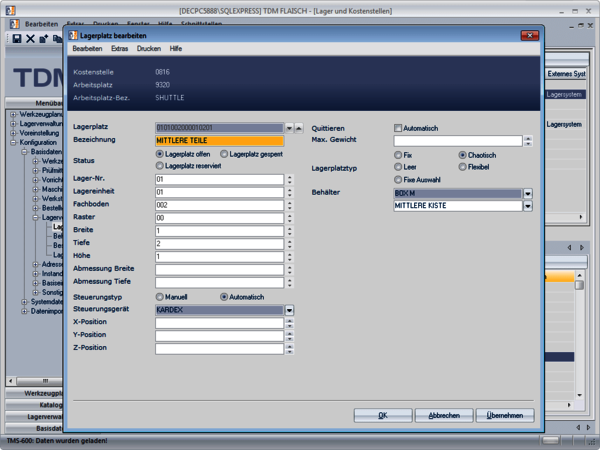

Centralized tool cribs also operate with paternoster and lift systems. They make use of the expensive manufacturing area very well because they can be built up to the ceiling of the manufacturing hall. Here, chaotic and location-coded crib strategies can be combined, which in turn has the advantage that the company can use ideally the available space. Maier: "Clear allocation is required so that people know at all times where the tools, measuring and inspection equipment, and fixtures are located." TDMstoreasy cabinet management can control all common cabinet types on the market. It can be linked to the TDM Tool Crib Module, but it can also be used stand-alone. "As a result, controlled tool dispensing and centralized evaluation for all of the connected cabinets are possible."

Condition and Location

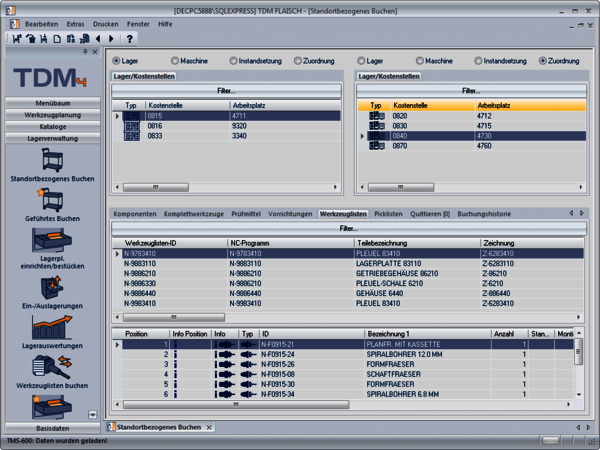

The TDM Tool Crib Module maps not only the crib, but also all of the upstream and downstream processes of a tool crib. TDM itself forms the connection between the existing system landscape and the tool crib and supports these with status information about the actual status of the production resources. Maier explains: "The software records the condition and location for each tool. Thus, it is clear whether they are tools that are new, used, or in need of repair." All logistics-related aspects can be detected, that is, whether and when an item was ordered, whether it is partially delivered or delivered. TDM combines up to six tool conditions under one ident no. This allows resource-oriented planning, which eliminates bottleneck situations and even machine downtimes due to missing tools.

The Tool Crib Module also provides information about whether tools are currently in circulation (that is, mounted on the machine), being disassembled, in the crib, or have been sent out for repairing. Various booking functions allow the booking of tools to cost centers, for example, to a machining center. "It is always clear in which tool assembly individual items are installed and where exactly the tools are right now."

After use, tool assemblies are stored in the assembled or disassembled state during rebooking. The Tool Crib Module supports the dispensing process and automatically provides the employee with the necessary instructions. During disassembly, the employee is able to see exactly what is to be done with each part. "The TDM module is practically the assistant who thinks along with you," says Maier.

Tool Lifecycle Management

Tool cribs are an important basic function in the comprehensive Tool Lifecycle Management process. Gathering the tool and production resource stocks and providing information about their condition and location form a solid basis for planning tools, orders, and machine occupation. The TDM Tool Crib Module even supports the ordering process and can handle order management of the tools automated in combination with the TDM Purchase Requisition Module.

If colleagues in NC programming also have access to the Tool Crib Module, then this information enables scheduling of the available tools early on during the planning phase. The advantage: the variety of tools remains manageable because new tools do not have to be planned in each time. The company can use its available tools optimally and thus reduce costs. Andreas Maier: "The TDM Tool Crib Module creates transparency and makes your tool organization economically efficient."

![[Translate to English:] Lagerhaltung Lift [] Lagerhaltung Lift](/fileadmin/media/news_and_media/press/specialist_articles/2016/lager-paternoster.png)