Take advantage of savings potential on the shopfloor – there will be even more!

There is still a high potential for savings on the shopfloor, which you can achieve by optimizing processes and managing data. TDM Systems has extensive expertise in organizing tool flows at the shopfloor level. This expertise is fully incorporated into the new Shopfloor Manager. The users receive software that helps them to define, visualize and organize all processes. Once this process is started, it enables the users to achieve cost and time savings. Secondly, you can always work with reliable procedures.

The Shopfloor Manager covers three key functional areas:

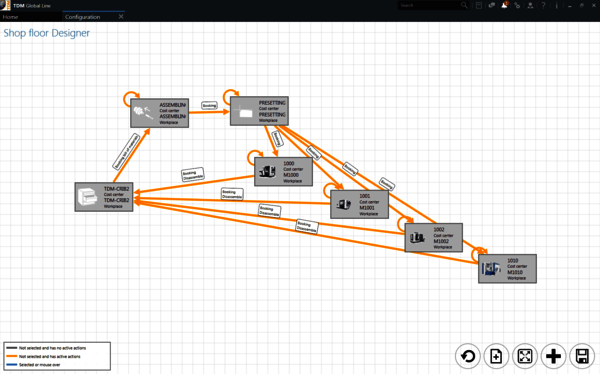

- Visualization of the shopfloor processes

- Navigation of the tool circulation

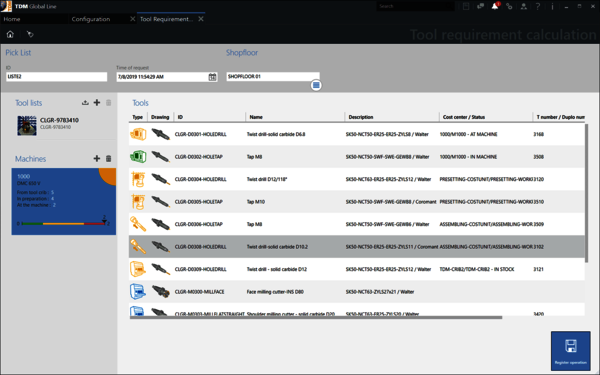

- Demand calculation for tools

The processes are visualized using a configurator. As a result, the customer receives a visual presentation of all of the stations which the tools are going through: Starting with the tool crib, via the assembly and presetting, and through to the machine. If the stations are defined, the individual tool circulation planning can begin. The stations are defined as cost centers to which you book the tools, depending on the process step. You can therefore always see at which preparatory stage the tools for an order are currently located. The integrated demand calculation for tools provides the optimum level of reliability for the tool availability: Based on the tool lists from the NC programs and the tools on the machine, the Shopfloor Manager calculates which tools are required for an order. This means that only the tools that are actually required for the shopfloor are prepared.

An optional networking of the machines with the TDM Shopfloor Manager enables the realization of Industry 4.0 standards in practice. Hence, you realize an ideal utilization of your machine park.

Adding the Tool Crib Module further increases the savings potential

Ideally, you should combine the TDM Shopfloor Manager Global Line with the TDM Tool Crib Module Global Line inventory management. This allows you to manage even tool assemblies in secondary cribs and near the machine. As such, employees always know exactly where the tool assemblies are and what condition they are in. Disassembling, reassembling and presetting are no longer strictly necessary, significantly saving time and costs. This provides the user with an optimum overview of the tool circulation.

How do successful TDM customers work?

TDM customers who manage their tool circulation achieve high levels of savings and transparency. Testfuchs, an Austrian manufacturer of test systems for the aviation and aerospace industries, is using TDM solutions to achieve absolute tool transparency on the shopfloor. The Shopfloor Manager is also a helpful tool for contract manufacturers: Thanks to their use of TDM solutions, Kempf, a medium-sized German company, is achieving almost 100% machine utilization.