"The global, sustainable innovator, DMG MORI, with whom we have been a partner for many years, wanted to link a DMC 160 FD duoBLOCK to TDM for its Swiss customer Bruderer – a technological trendsetter in stamping technology," explains Volker Schwegler, Engineering Consultancy team leader at TDM Systems, describing the start of an exciting project with interesting prospects. The milling and turning all-in-one machining center with the app-based control and operating system CELOS is a step towards intelligently networked production. ToolFilter maintains an overview of tools.

DMG MORI had taken a step forward with the "ToolFilter" software application that it had developed itself for its Siemens controller. Thomas Lochbihler, Head of Technology Excellence at the DMG MORI plant in Pfronten, comments on this function. "The application, which also carries out direct data exchange with the machine control system, gets going as soon as one of the machine's ten machine pallets has been filled. It checks whether the tools needed for the relevant NC program are available in the magazine and their condition. Having done this balancing, it shows missing tools and information about available tools on the screen."

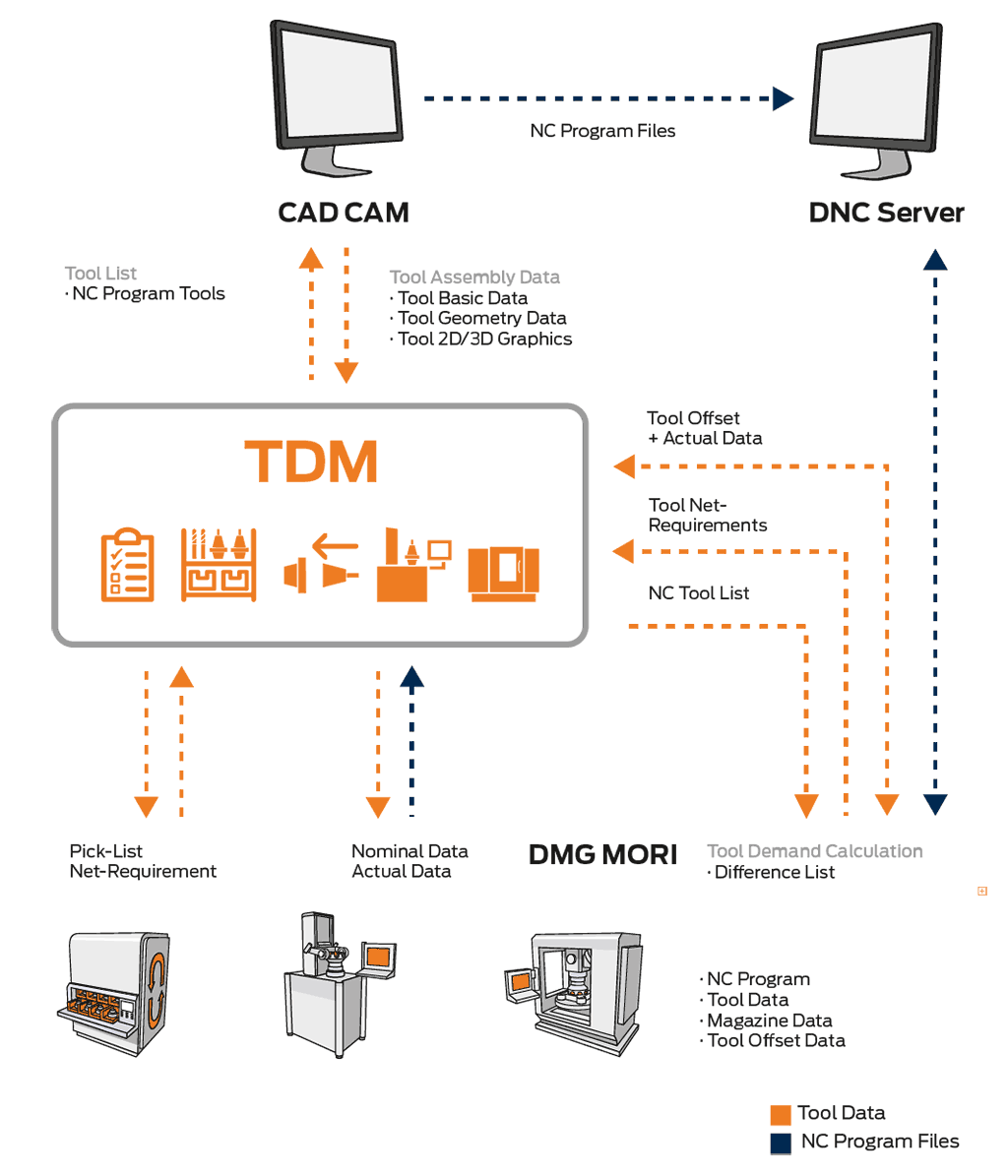

This data now uses TDM software. Schwegler: "We have developed an interface for this that can receive and understand the data." TDM already had experience with such interfaces from an interface with a similar function – an interface to a specialist software for connecting machines and systems whose services use TDM if there is no corresponding software from the machine manufacturer. TDM can, however, also take a two-pronged approach if a single shopfloor contains machines from different manufacturers. What makes that possible is the very flexible TDM Shopfloor Manager, which can either do the planning itself or leave this procedure to the machine.

Fully digitalized cycle

The interface developed by TDM Systems for DMG MORI, based on a web service, currently offers three main functions. Firstly, it receives a tool requirement notification from the tool machine controller. TDM creates a pick list from these requirements and derives a presetting order from this.

Through presetting, the tool becomes a unique inventory tool and receives a unique holder ID, which is, in this case, imprinted on the toolholder in the form of a data matrix code. In principle, according to Schwegler, any other form of identification could also be used for this, for example an RFID chip or a simple tool number entered manually – it just has to be unique. With it, TDM can manage several similar tool assemblies, which of course differ in their actual data, in parallel. It also takes care of potentially necessary sister tools for one or several machines.

The tool is transported from the presetting area to the machine, ready for use. There, the application scans the holder ID and retrieves the tool's actual data from TDM. "TDM sends all tool data about precisely this tool directly to the machine control system," explains Schwegler. "Directly" can be understood literally, because the data is passed on to the machine control system on a one-to-one basis. Everything must be correct here, to avoid any machine down time.

Mapping performs allocation work

"To ensure that this goes smoothly, we develop a mapping for each machine control system, to allocate the values correctly. This works in a similar way to the CAM and simulation systems interfaces," says Schwegler. This is a lot of work for the TDM Systems experts, because the formats differ depending on the controller, the machines and the requirements of the machine manufacturer's magazine management.

It is especially challenging if it concerns a DMC 125 FD duoBLOCK, as in this specific case. The milling and turning all-in-one machining center is available with a spindle of up to 1800 Nm and is extremely precise thanks to its robust design and intelligent cooling system. "Such powerful and precise machines have very strict requirements when it comes to the quality of tool data – and we adapt this down to the smallest detail from machine type to machine type." However, not all controllers are the same here. Schwegler considers the proportion of identical functions to be about 80%. The remaining 20%, the OEM parameters, come from the machine manufacturer. These even differ between different series and machine types from the same manufacturer.

What it really looks like

What is especially exciting when it comes to digitalization and Industry 4.0 is an interface function that Schwegler describes as follows: "We receive up-to-date information on the condition of the tools in the machine from the controller and now know precisely how the tool looks after the spindle has been used, what the remaining tool lifetime is or whether it is broken. This gives us the opportunity to respond in good time and inform the machine operator in preparation."

The "Tool Report" consequently provides a real-life status notification about every tool in use, in a way that was not previously possible. This way, not only planning but also actual demand for tools can now be determined in good time, bearing in mind the service life of the tools. This also means that it is no longer a problem to provide sister tools in good time, Thomas Lochbihler from DMG MORI is happy to say: "This lets our customers make significant savings when it comes to setup times and provides them continuous, uninterrupted production."