Feature-Based Machining – what does that actually mean? By "features", the CAM systems are referring to individual operations which are programmed and performed at the machine at a later point. Example: drilling a hole and cutting an M8 thread. A variety of operations are required to create an NC program, many of which are continuously repeated on the workpieces that are being machined. To eliminate the need to define and program these operations anew each time, you can set them as a feature in the CAM system. In this way, NC programming is becoming automated to a certain extent.

There's now good news for TDM and SIEMENS NX users

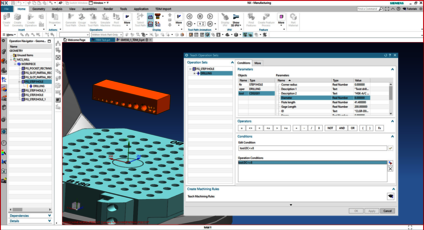

TDM supports Feature-Based Machining with its CAM interface to NX. The search process directly accesses the tool assemblies created in the TDM database. They are primarily filtered according to the criteria of machine adapter and material. Other criteria are easy to create in the NX MKE Editor. NX also offers a teaching approach, which makes it possible to automatically link operations with potential tool parameters in the NX knowledge library. The TDM NX interface also supports this process. The identified tools are directly loaded to NX without the need for an additional command.

TDM users of the TDM Base Module and the TDM CAM integration NX were already able to select tools based on various criteria using the tool search functions and load them to NX. However, this process previously had to be performed separately for each machining step. Now elements of the NC program creation process are automated, including toolscheduling, which leads to dramatic improvements, especially reduced amount of time. In addition, mainly predefined stock tools are scheduled, which reduces tool stock and makes it possible to plan tool use.

The benefits are obvious

All in all, you can achieve greater agility in production planning. On the basis of the real tool stock, the system selects tool assemblies for machining operations – in a fast, application-specific and automatic process. The connection between FBM and TDM ensures dramatically increased efficiency in NC planning, especially when production is made up of variant-rich workpieces or batch size 1. Available and simulation-ready tool data and graphics form the ideal starting point for realistically simulating machining processes, thereby shortening the lead times. Know how is no longer lost. Rule- and feature-based programming enables company-specific standards to be defined and used in program-ming.

Typical errors encountered in manual programming are prevented, while new or less experienced staff can easily complete their assigned tasks. This also leads to a reduction in machine downtimes as orders only reach the machines which have all the necessary tools available. Useful addition for perfect interaction: The 3D Converter from TDM for 3D preparation of tool models in line with NX requirements.